High Speed TPU offers premium, fast D printing, performing 3-5 times quicker than standard TPU while maintaining quality. Ideal for rapid projects, store it dry and preheat if stored long-term for best results.

Overture TPU High Speed 3D Printer Filament 1.75mm

Product Features

- High Flow Rate

- Flexibility and Durability

- Ease of use

- Rapid 95A TPU

- Clog-Free & Bubble-Free

Cautions for Use

- Must dry out before use

- AMS & AMS lite NOT Compatible

Couldn't load pickup availability

You May Also Like

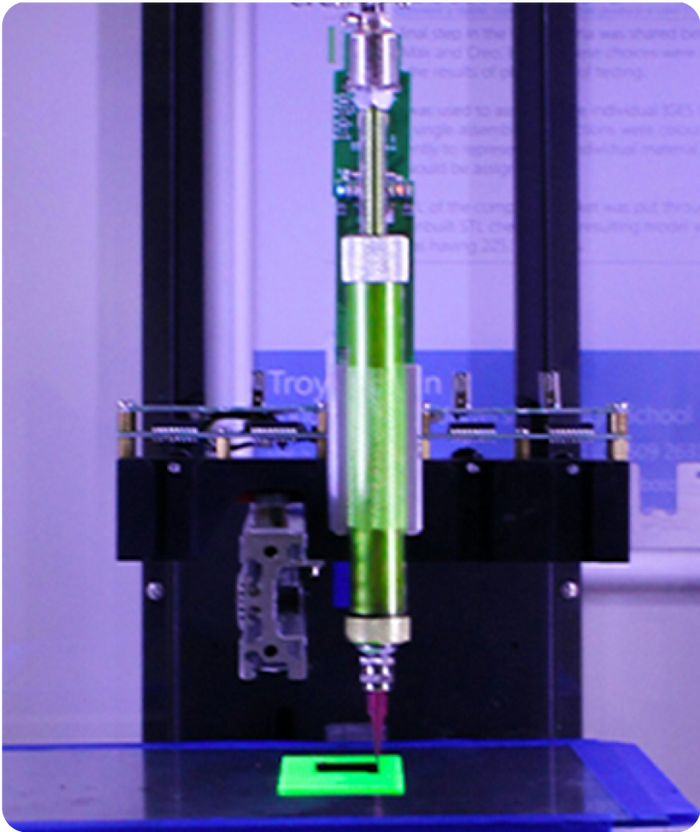

High Flow Rate

High Speed TPU is designed with a high melt index, allowing it to be printed 3 to 5 times faster than TPU filaments. This high flow rate enables quicker production times, making it ideal for projects that require efficiency without compromising quality.

Flexibility and Durability

High Speed TPU retains the excellent flexibility and durability inherent to TPU materials. It can withstand bending and stretching, making it suitable for applications that demand both resilience and pliability, such as custom parts, wearable devices, and functional prototypes.

Ease of Use

High Speed TPU is easy to work with, making it suitable for both beginners and experienced users. It allows you to focus more on your creative projects and can achieve good results when your first try.

Hex Code

Recommended Printing Settings

| Nozzle temperature | 200 - 240 °C |

| Build Surface material | OVERTURE Build Surface, Textured PEI, Blue Tape |

| Build surface treatment | None / Applying PVA glue to the build surface |

| Build plate temperature | 25 - 60 °C |

| Cooling fan | Turned on |

| Printing speed | 60 - 90 mm/s |

| Retraction distance | 1-3 mm |

| Retraction speed | 20-40 mm/s |

| Threshold overhang angle | 35 ° |

Packaging Box

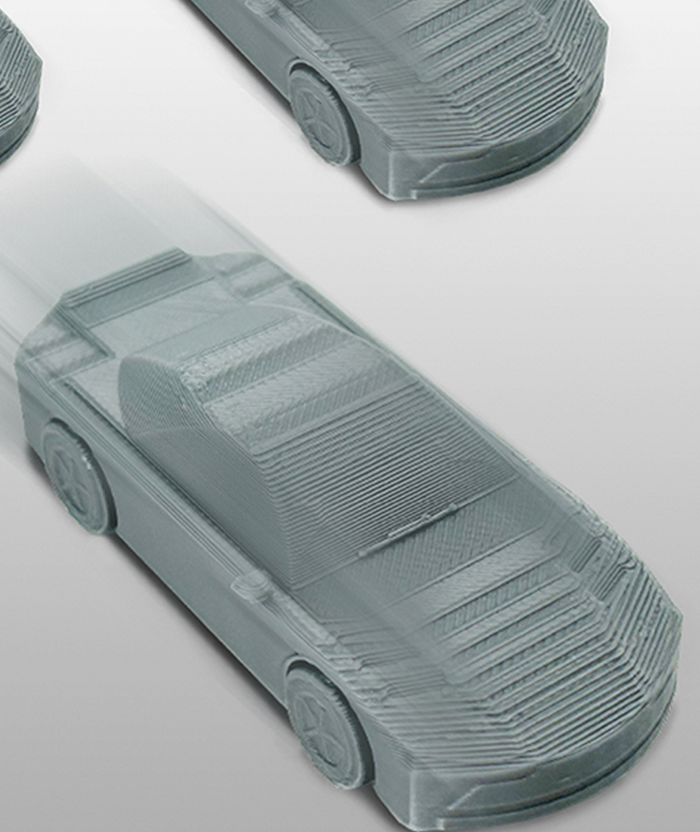

Prints Display

FAQ

Can AMS be used with HS TPU?

Can AMS be used with HS TPU?

It depends on the specific printer and AMS setup. The distance between the extruder and nozzle in AMS can be too far, which may stretch the filament and cause deformation, leading to inaccurate extrusion. As a result, some printers may restrict the use of AMS for printing TPU altogether.

Can a Bowden extruder be used with HS TPU?

Can a Bowden extruder be used with HS TPU?

A Bowden extruder can be used with HS TPU, but it requires more careful adjustments. Also, print quality will typically be superior when using a direct extruder for flexible materials like TPU.

Is HS TPU humidity sensitive? Any drying recommendations?

Is HS TPU humidity sensitive? Any drying recommendations?

Yes, HS TPU is sensitive to humidity. It is recommended to dry TPU-based filaments at 70°C (158°F) for 7 hours to ensure optimal print quality. Avoid extended drying times, as this can lead to the filament becoming brittle and unsuitable for printing. For storage, keep it in a sealed container with desiccants to maintain low humidity levels.

What does 95A mean?

What does 95A mean?

The "95A" refers to the shore hardness of the TPU material. Shore A is a scale used to measure the hardness of flexible materials, and 95A indicates that the material has a certain degree of deformability. You can manipulate the softness by adjusting the structural design and infill settings.