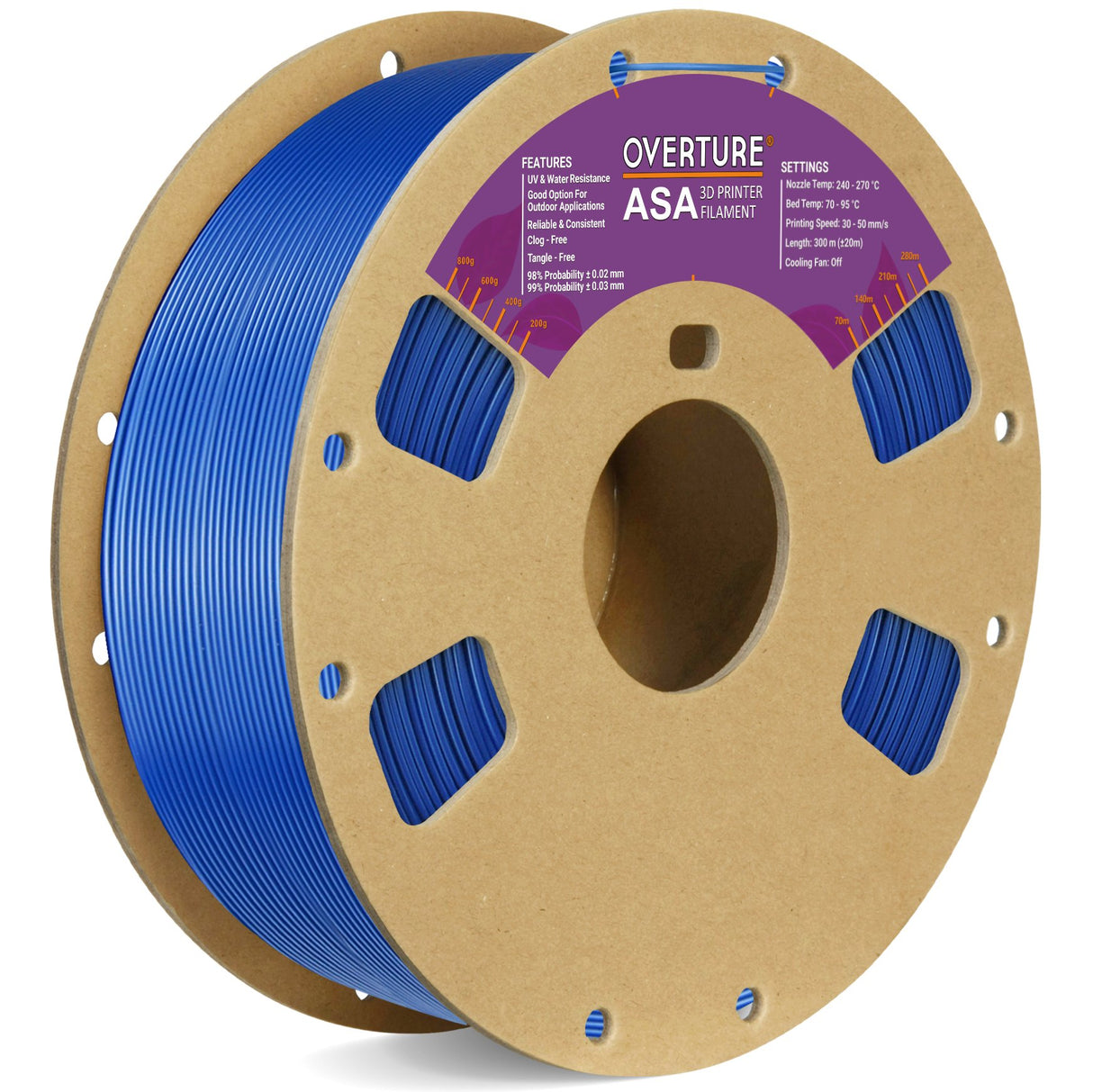

OVERTURE ASA, a high-performance filament that serves as an excellent alternative to traditional ABS, offering enhanced weather resistance and UV protection. It is perfect for outdoor fixtures, automotive components, and other applications exposed to the elements. Experience the reliability and resilience of OVERTURE ASA, and ensure your 3D printed projects endure the test of time and weather!

Weather Resistance

OVERTURE ASA is designed to withstand a variety of environmental conditions, making it highly resistant to rain, humidity, and temperature fluctuations. This weather resistance ensures that printed parts maintain their structural integrity and performance over time, even when exposed to the elements.

Good Mechanical Properties

OVERTURE ASA exhibits impressive mechanical properties, providing strength and durability comparable to traditional ABS. This filament's robust nature allows it to withstand impact and stress, making it suitable for a wide range of applications.

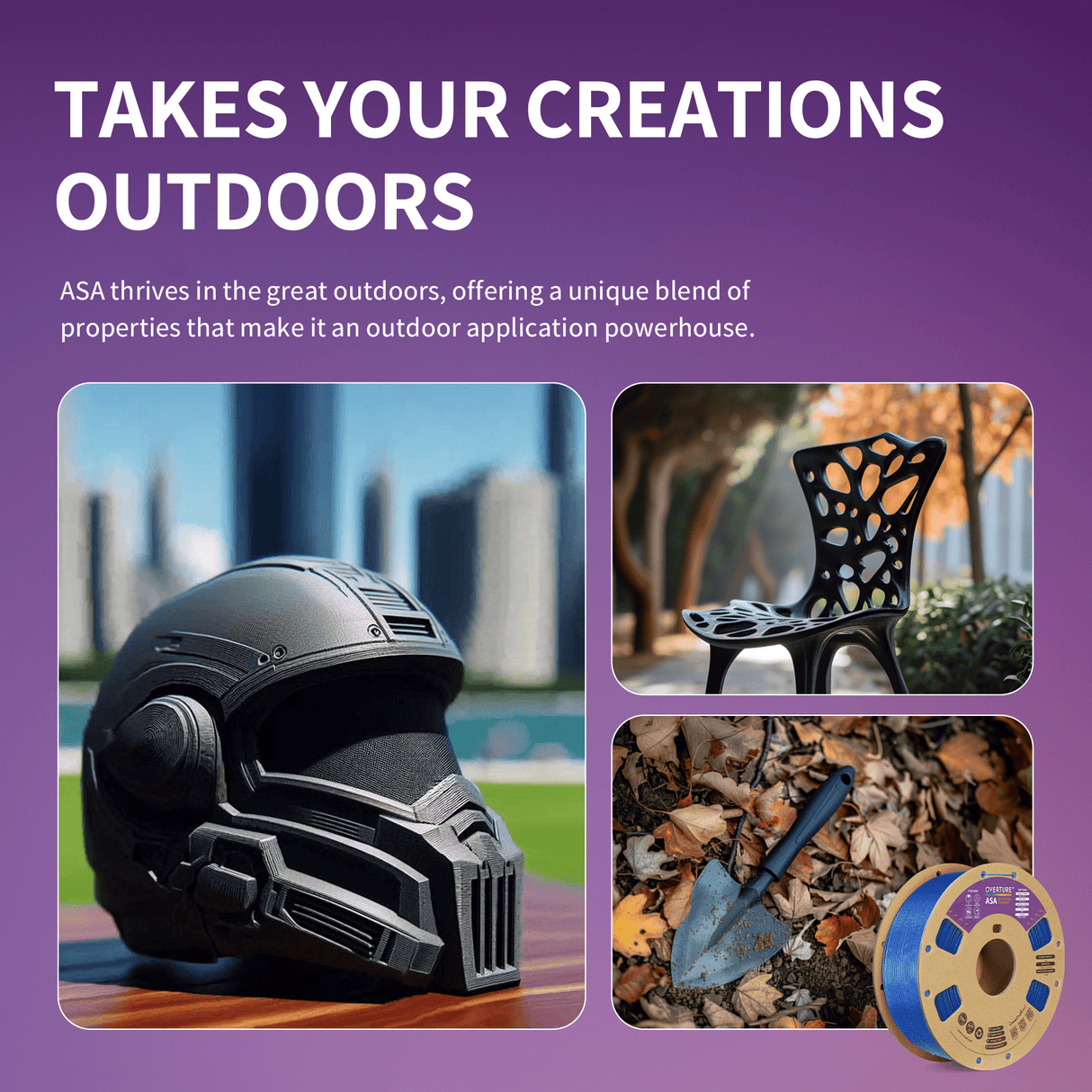

Outdoor Application

Thanks to its weather and UV resistance, OVERTURE ASA is the ideal choice for outdoor applications. Its ability to endure exposure to the elements while maintaining structural integrity makes OVERTURE ASA a versatile option for any project requiring durability and longevity outdoors.

Prints Display

Recommended Printing Settings

| Nozzle temperature | 240 - 270 °C |

| Build Surface material | PA film, PI film, Textured PEI |

| Build surface treatment | Applying PVA glue to the build surface |

| Build plate temperature | 70 - 95 °C |

| Cooling fan | Turned off |

| Printing speed | 30-50 mm/s |

| Retraction distance | 1-3 mm |

| Retraction speed | 20 - 40 mm/s |

| Threshold overhang angle | 50 ° |

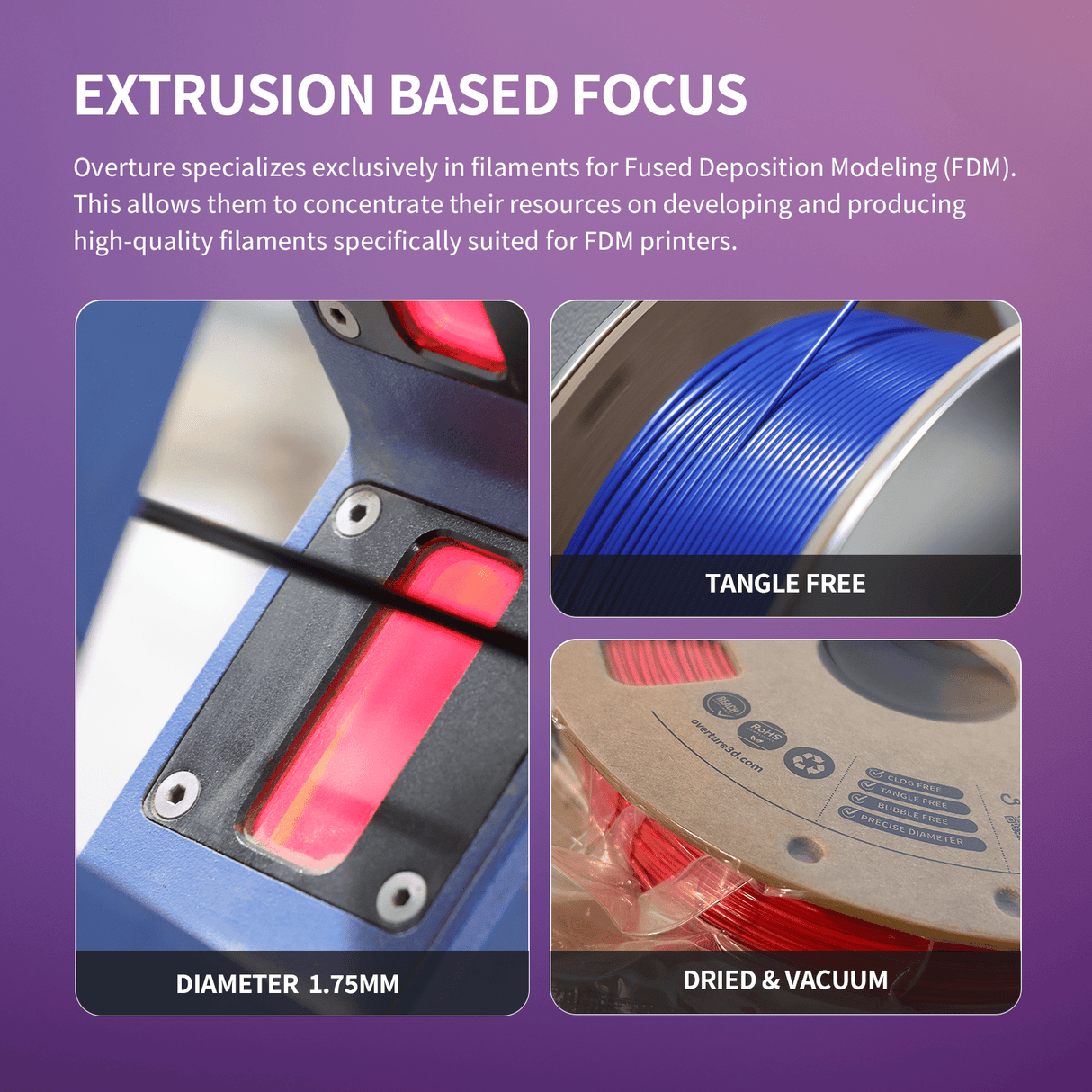

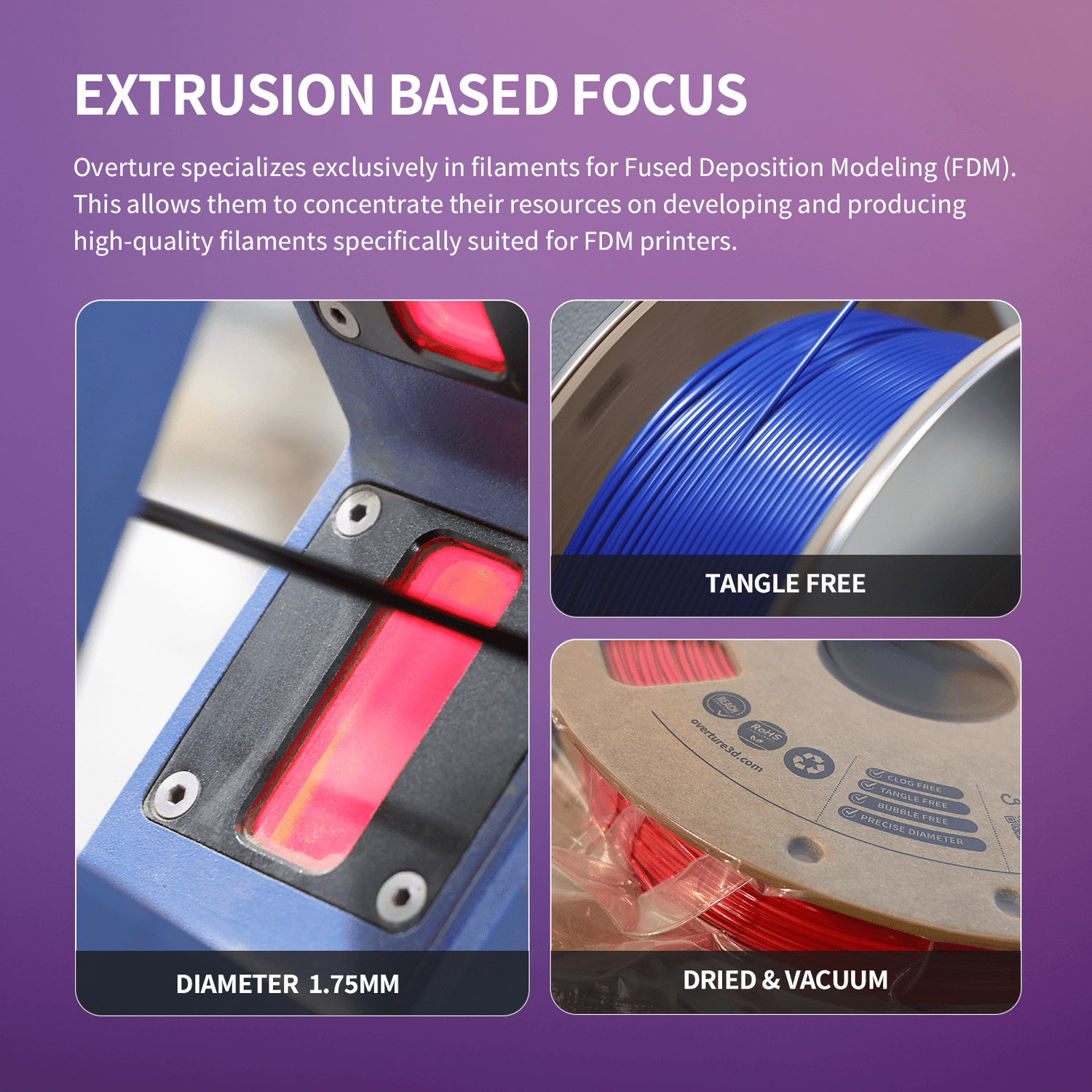

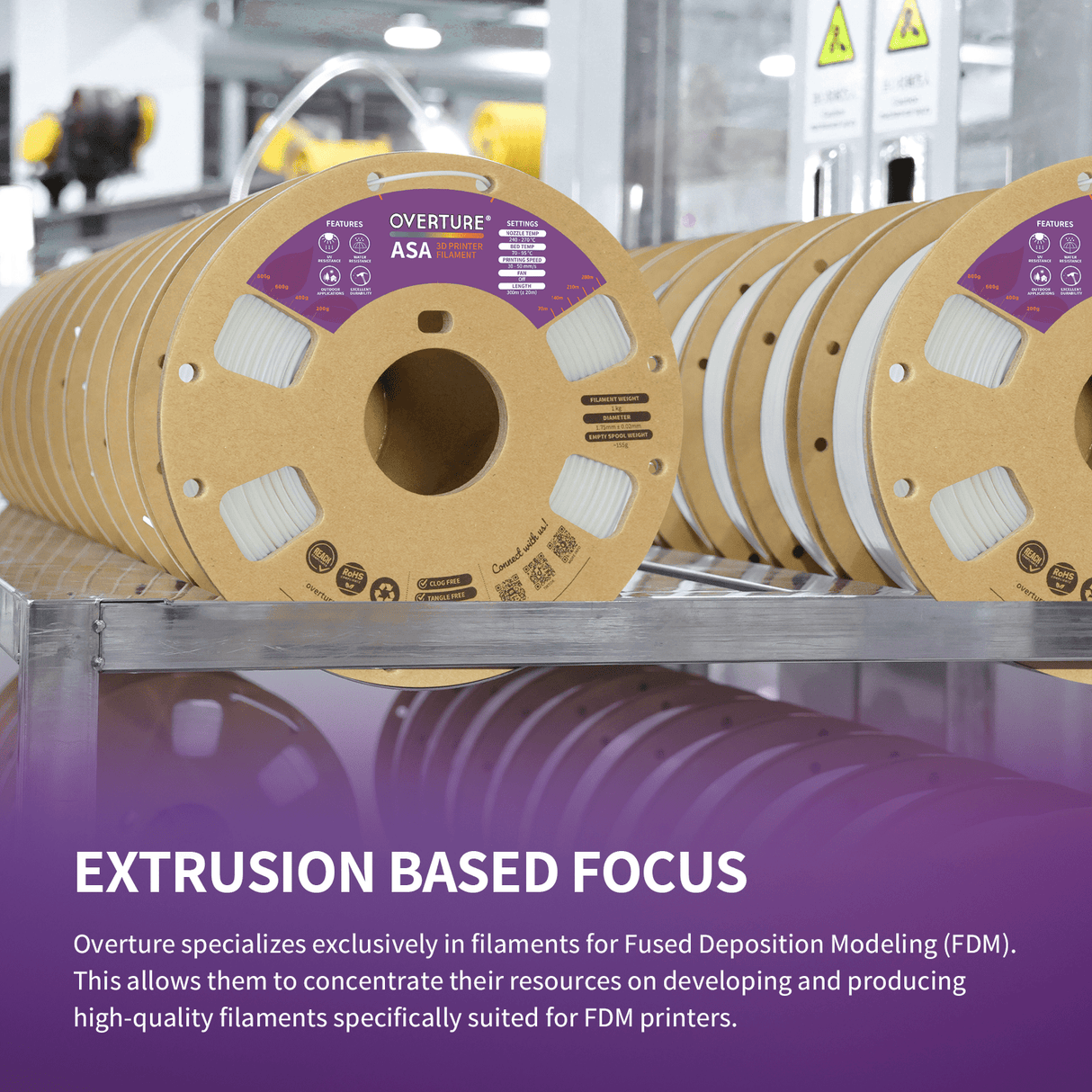

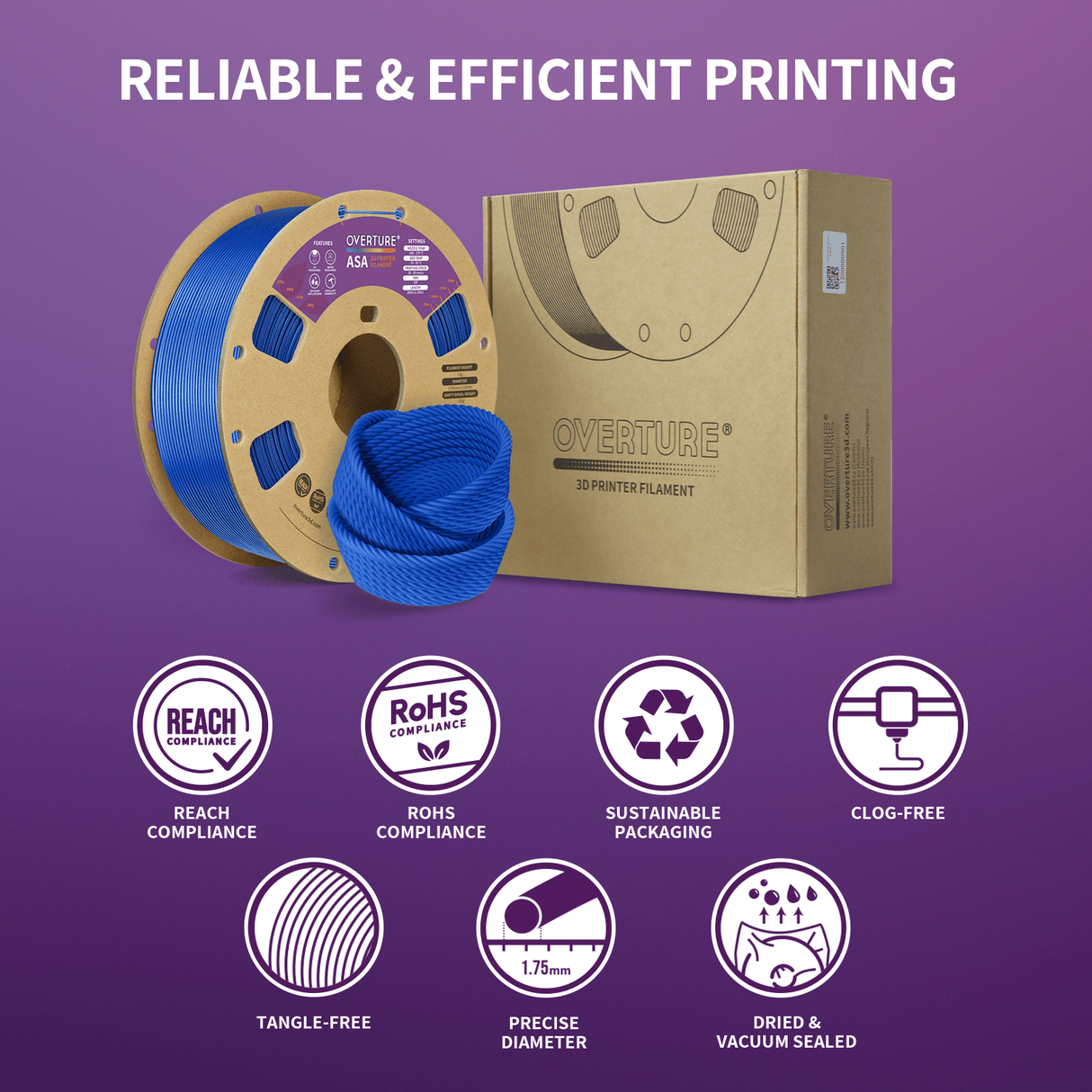

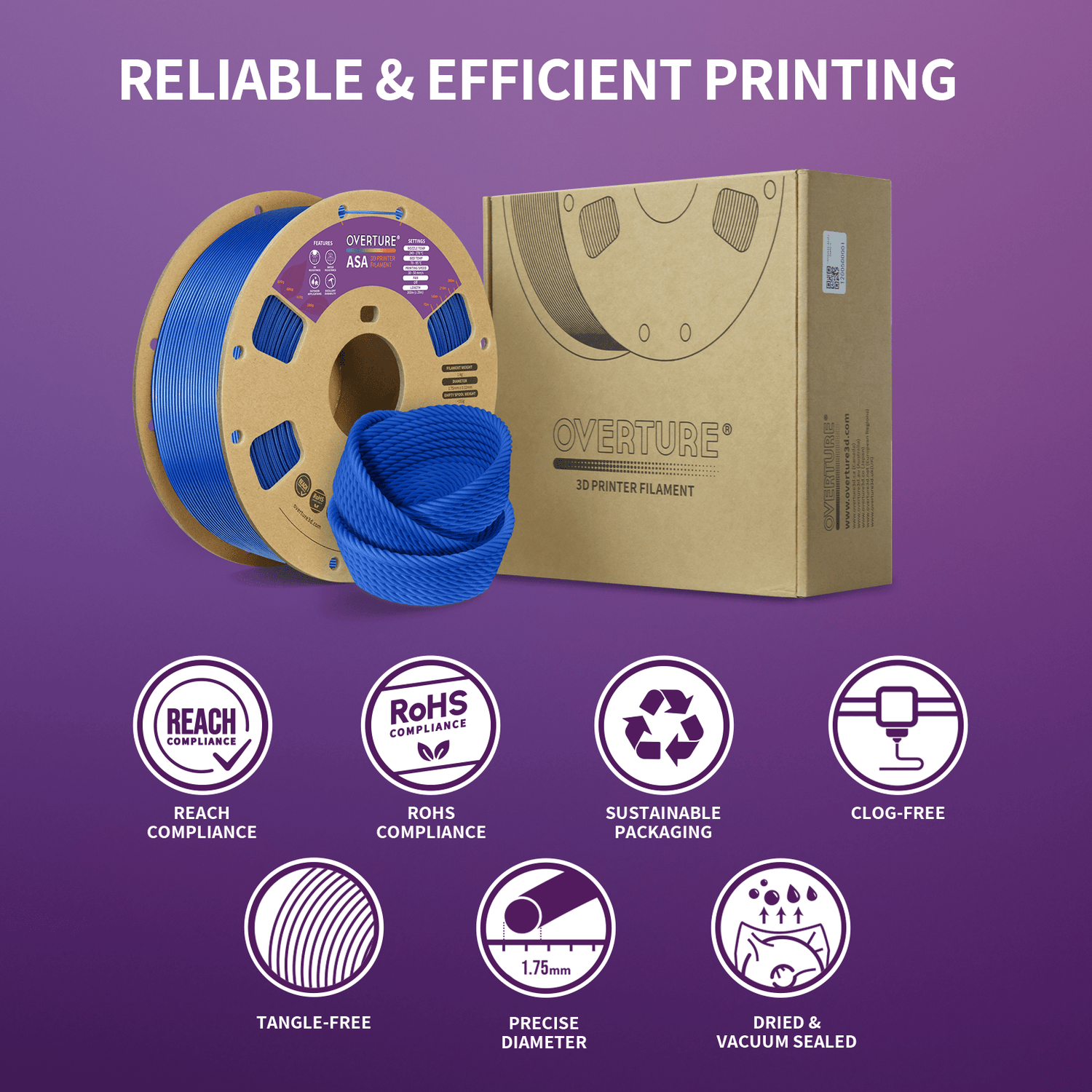

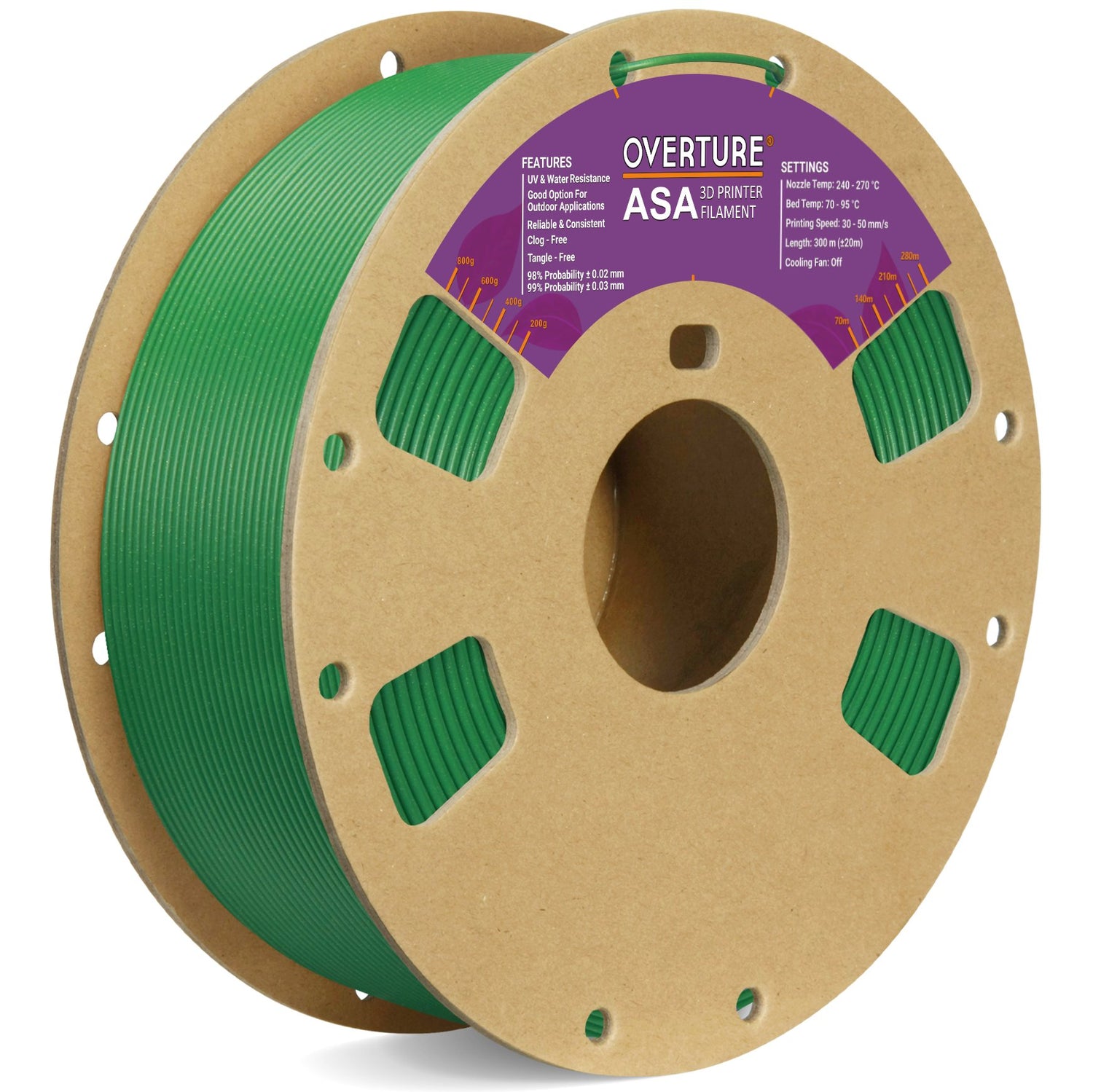

Packaging Box

FAQ

What's the difference between Overture ASA and ABS?

What's the difference between Overture ASA and ABS?

Overture ASA offers superior UV resistance and greater stability in outdoor environments compared to ABS, making it ideal for outdoor applications. ASA is also considered to have a lower level of toxicity and produces less noticeable fumes, making it a safer option for enclosed spaces. In contrast, ABS is generally more affordable and easier to source.

Does the Overture ASA smell when you print it? Is it toxic and harmful?

Does the Overture ASA smell when you print it? Is it toxic and harmful?

While Overture ASA does produce some odor during printing, the emissions are generally less harmful compared to those from ABS. However, it’s always wise to take appropriate safety precautions, including ensuring good ventilation and considering air filtration when printing with ASA or any other thermoplastic.

Does the Overture ASA need to be dried before print?

Does the Overture ASA need to be dried before print?

Yes, ASA is sensitive to moisture, so we recommend drying ASA under 75°C(167°F) for 7 hours. Avoid extended drying times, as this can lead to the filament becoming brittle and unsuitable for printing. For storage, keep it in a sealed container with desiccants to maintain low humidity levels.

How does Overture ASA perform in terms of heat resistance?

How does Overture ASA perform in terms of heat resistance?

Overture ASA displays excellent heat resistance, featuring a Vicat Softening Temperature of 106.2°C, as measured according to ISO 306 and GB/T 1633 standards. This makes it a suitable choice for applications that may involve exposure to elevated temperatures, especially for outdoor use.

For reference, the Vicat Softening Temperatures of other engineering filaments are as follows:

- ABS: 103.4°C

- PETG: 85.1°C

- Easy Nylon: 181.2°C

- PC Professional: 110.3°C