Prints Display

Recommended Printing Settings

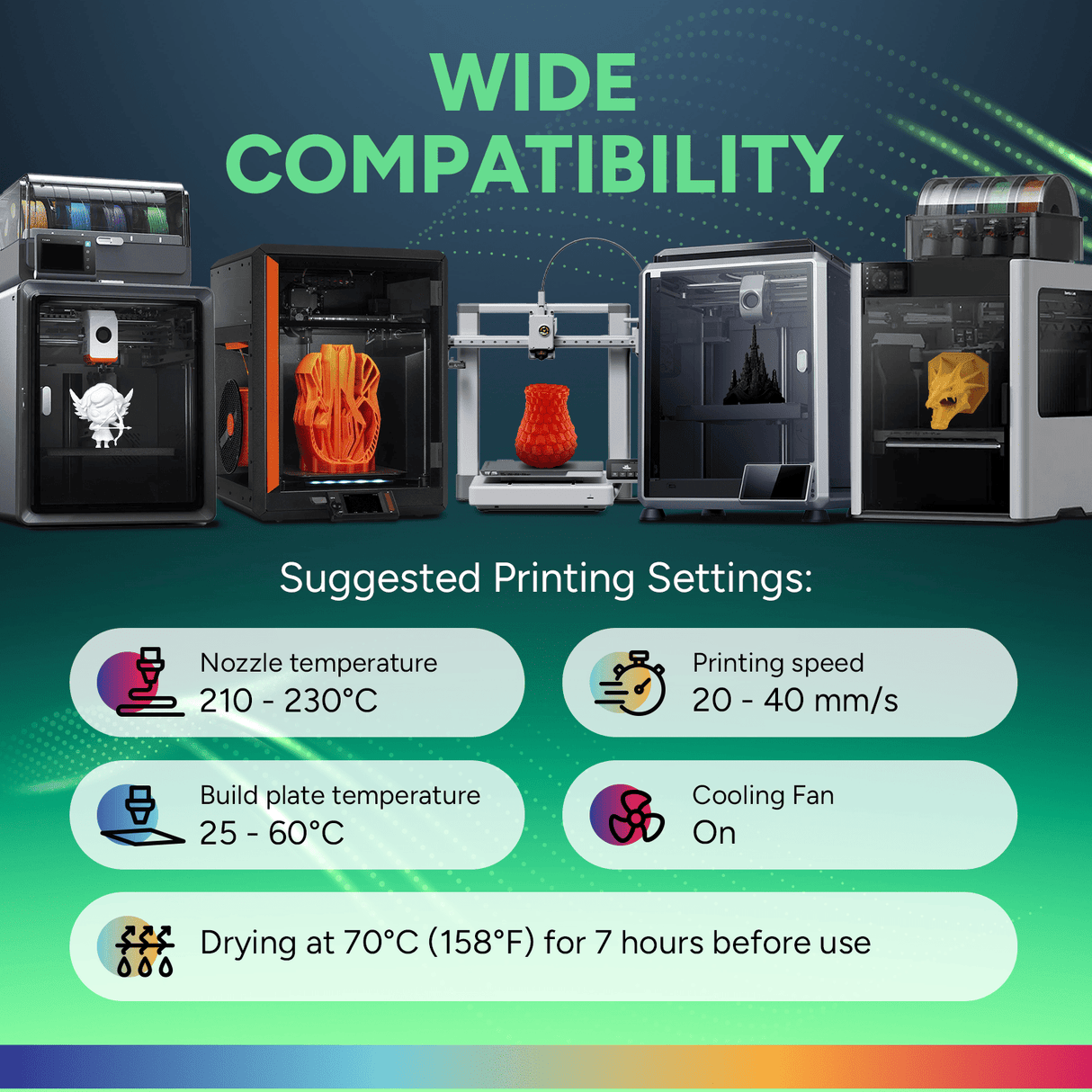

| Nozzle temperature | 210 - 230 °C |

| Build Surface material | OVERTURE Build Surface, Textured PEI, Blue Tape |

| Build surface treatment | None / Applying PVA glue to the build surface |

| Build plate temperature | 25 - 60 °C |

| Cooling fan | Turned on |

| Printing speed | 20 - 40 mm/s |

| Retraction distance | 1 - 3 mm |

| Retraction speed | 20 - 40 mm/s |

| Threshold overhang angle | 35 ° |

FAQ

Is TPU humidity sensitive? Any drying recommendations?

Is TPU humidity sensitive? Any drying recommendations?

Yes, TPU is sensitive to humidity. It is recommended to dry TPU-based filaments at 70°C (158°F) for 7 hours to ensure optimal print quality. Avoid extended drying times, as this can lead to the filament becoming brittle and unsuitable for printing. For storage, keep it in a sealed container with desiccants to maintain low humidity levels.

What does 95A mean?

What does 95A mean?

The "95A" refers to the shore hardness of the TPU material. Shore A is a scale used to measure the hardness of flexible materials, and 95A indicates that the material has a certain degree of deformability. You can manipulate the softness by adjusting the structural design and infill settings.