Overture Nylon Filament, a versatile and high-performance material designed for a wide range of applications. Known for its exceptional strength, durability, and flexibility, Nylon is an ideal choice for creating functional prototypes, mechanical parts, and intricate designs that require resilience and toughness. Its inherent resistance to abrasion and impact makes it suitable for demanding applications, including automotive components, industrial parts, and outdoor gear. The material can also be easily dyed or treated, providing endless possibilities for customization and creativity.

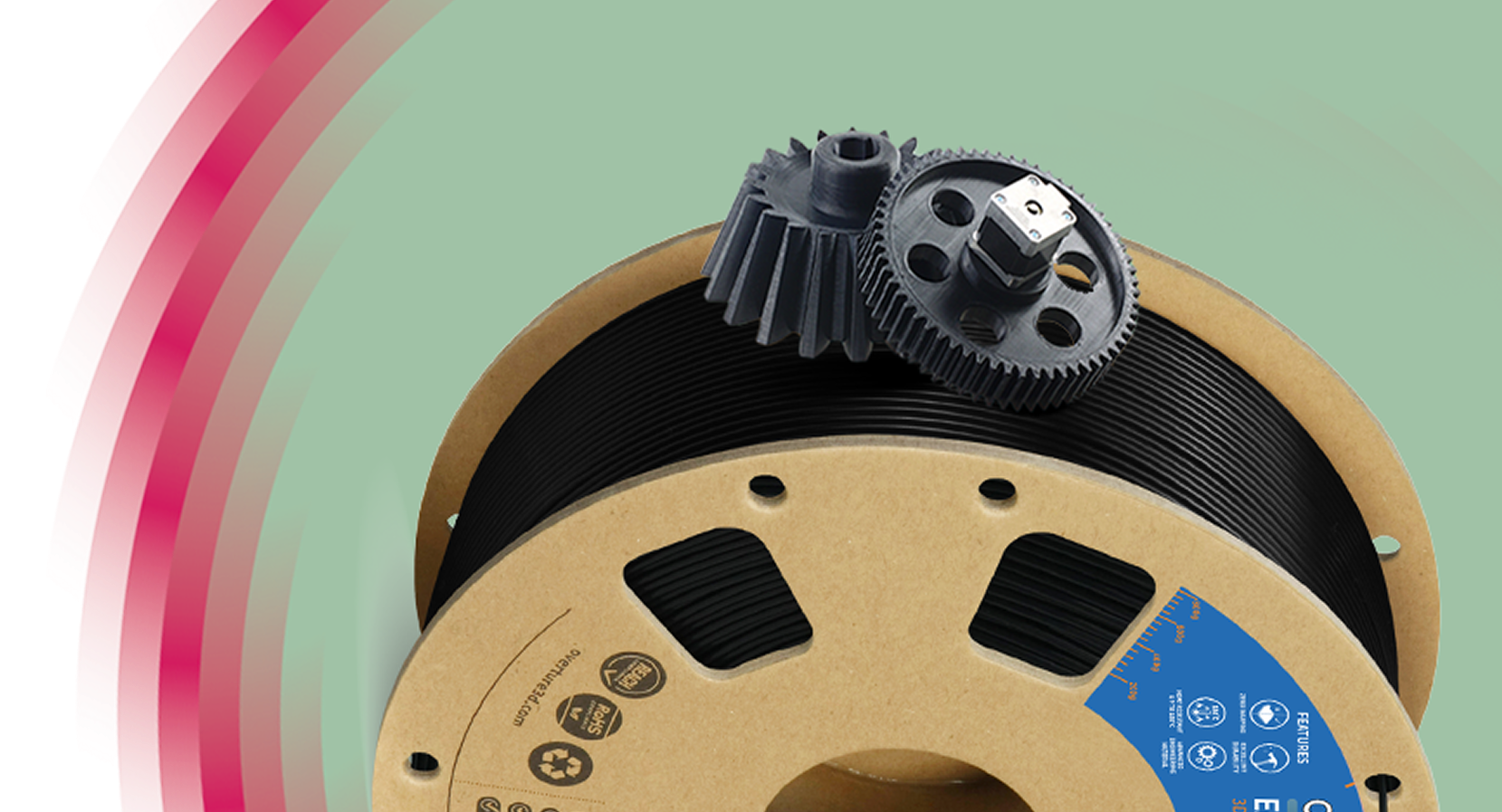

Overture Easy Nylon 3D Printer Filament 1.75mm

Product Features

- Exceptional Strength and Durability

- Excellent Layer Adhesion and Low Shrinkage

- Impact Resistance

Cautions for Use

- Enclosed Printer Required

- Hardened Nozzle Recommended

- Keep Dry

Couldn't load pickup availability

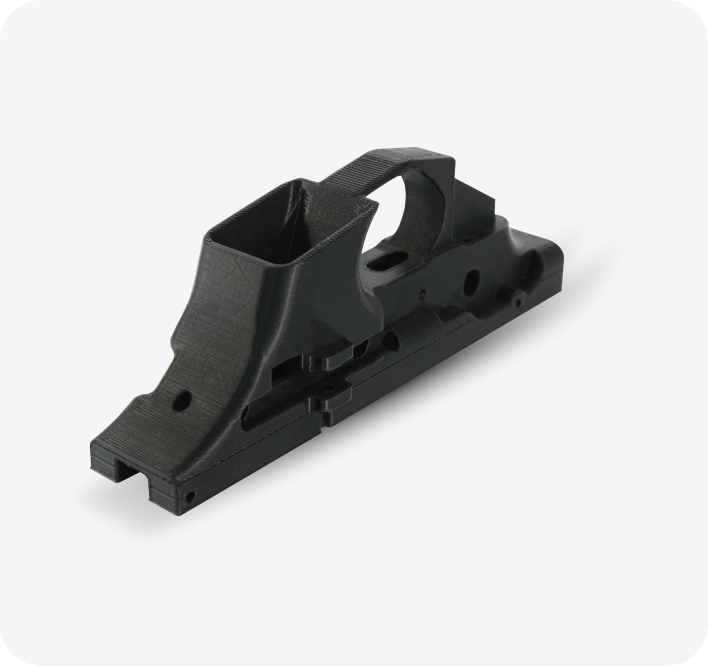

Exceptional Strength and Durability

Overture Nylon is known for its high strength and durability, making it an ideal choice for creating functional prototypes and mechanical parts that require resilience and toughness. This feature allows nylon prints to withstand significant wear and tear, making them suitable for demanding applications.

Excellent Layer Adhesion and Low Shrinkage

Overture Nylon exhibits excellent layer adhesion, which helps maintain the shape and integrity of the prints during the printing process. Additionally, its low shrinkage rate reduces the risk of warping and dimensional inaccuracies, resulting in more precise and reliable prints.

Impact Resistance

Overture Nylon possesses inherent resistance to abrasion and impact, making it suitable for applications that involve rough handling or exposure to stress. This property enhances the longevity and performance of printed parts in various environments, including automotive and industrial settings.

Hex Code

Recommended Printing Settings

| Nozzle temperature | 245 - 260 °C |

| Build Surface material | PA film, PI film, Textured PEI |

| Build surface treatment | Applying PVA glue to the build surface |

| Build plate temperature | 50 °C |

| Cooling fan | Turned off |

| Printing speed | 30-70 mm/s |

| Retraction distance | 3-6 mm |

| Retraction speed | 40 - 60 mm/s |

| Threshold overhang angle | 55 ° |

Packaging Box

Prints Display

FAQ

Does Overture Easy Nylon absorb moisture? How do I dry/store Overture Easy Nylon?

Does Overture Easy Nylon absorb moisture? How do I dry/store Overture Easy Nylon?

Yes, Easy Nylon is sensitive to moisture, so we recommend drying under 95°C (203°F) for 7 hours. Avoid extended drying times, as this can lead to the filament becoming brittle and unsuitable for printing. For storage, keep it in a sealed container with desiccants to maintain low humidity levels.

Is there a recommended printer for printing with Overture Easy Nylon? Can I use Bambu Lab A1 or Bambu Lab A1 Mini?

Is there a recommended printer for printing with Overture Easy Nylon? Can I use Bambu Lab A1 or Bambu Lab A1 Mini?

While there are no specific printer requirements for Easy Nylon, it is recommended to use an enclosed printer to maintain the necessary environmental temperature for optimal results.

Is Easy Nylon abrasive? What nozzle is recommended?

Is Easy Nylon abrasive? What nozzle is recommended?

Easy Nylon is slightly abrasive, so it's best to use a hardened steel nozzle or a nozzle designed for abrasive materials to prevent wear and prolong the lifespan of your nozzle.

Is annealing recommended for Easy Nylon?

Is annealing recommended for Easy Nylon?

Yes, annealing is recommended to enhance the mechanical and thermal properties of the printed part. The printed part will not reach full crystallization after the printing process, so an additional step is required: anneal at 80°C(176°F) for 6 hours to achieve optimal properties.

How does Overture Easy Nylon perform in terms of heat resistance?

How does Overture Easy Nylon perform in terms of heat resistance?

Overture Easy Nylon shows exceptional heat resistance, with a Vicat Softening Temperature of 181.2°C according to ISO 306 and GB/T 1633 standards. This makes it ideal for applications that require high thermal stability and durability under heat.

For reference, the Vicat Softening Temperatures of other engineering filaments are as follows:

- ABS: 103.4°C

- PETG: 85.1°C

- ASA: 106.2°C

- PC Professional: 110.3°C