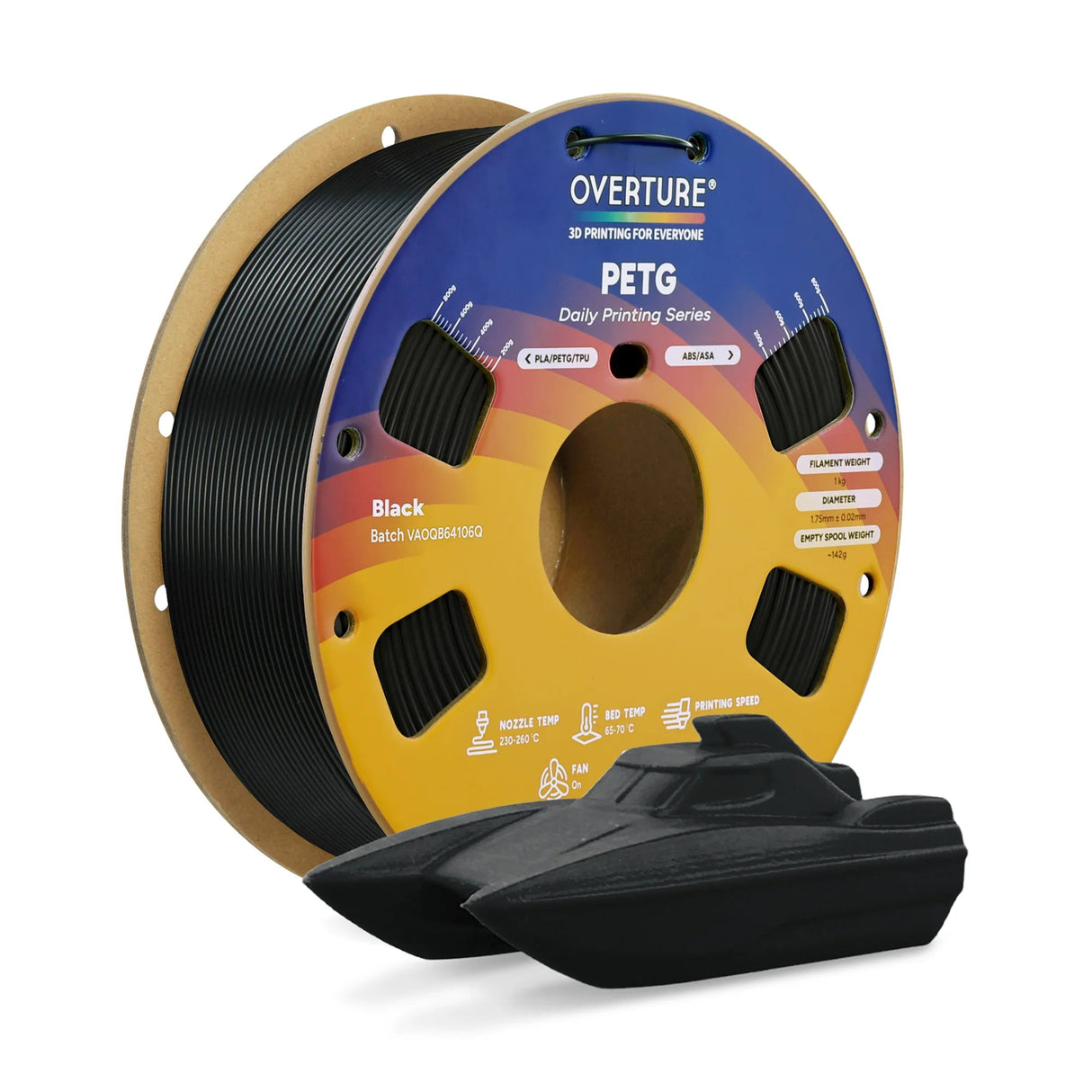

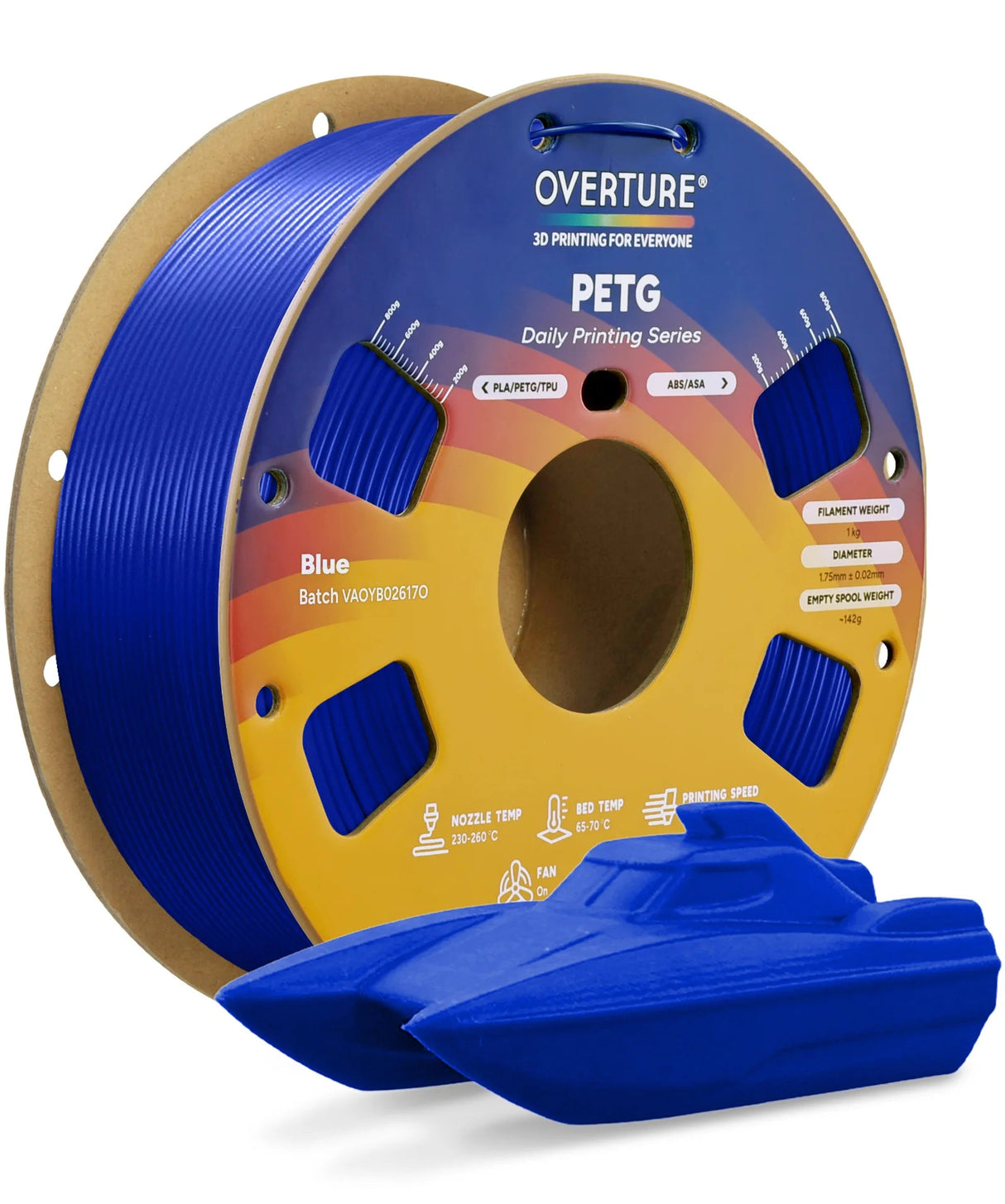

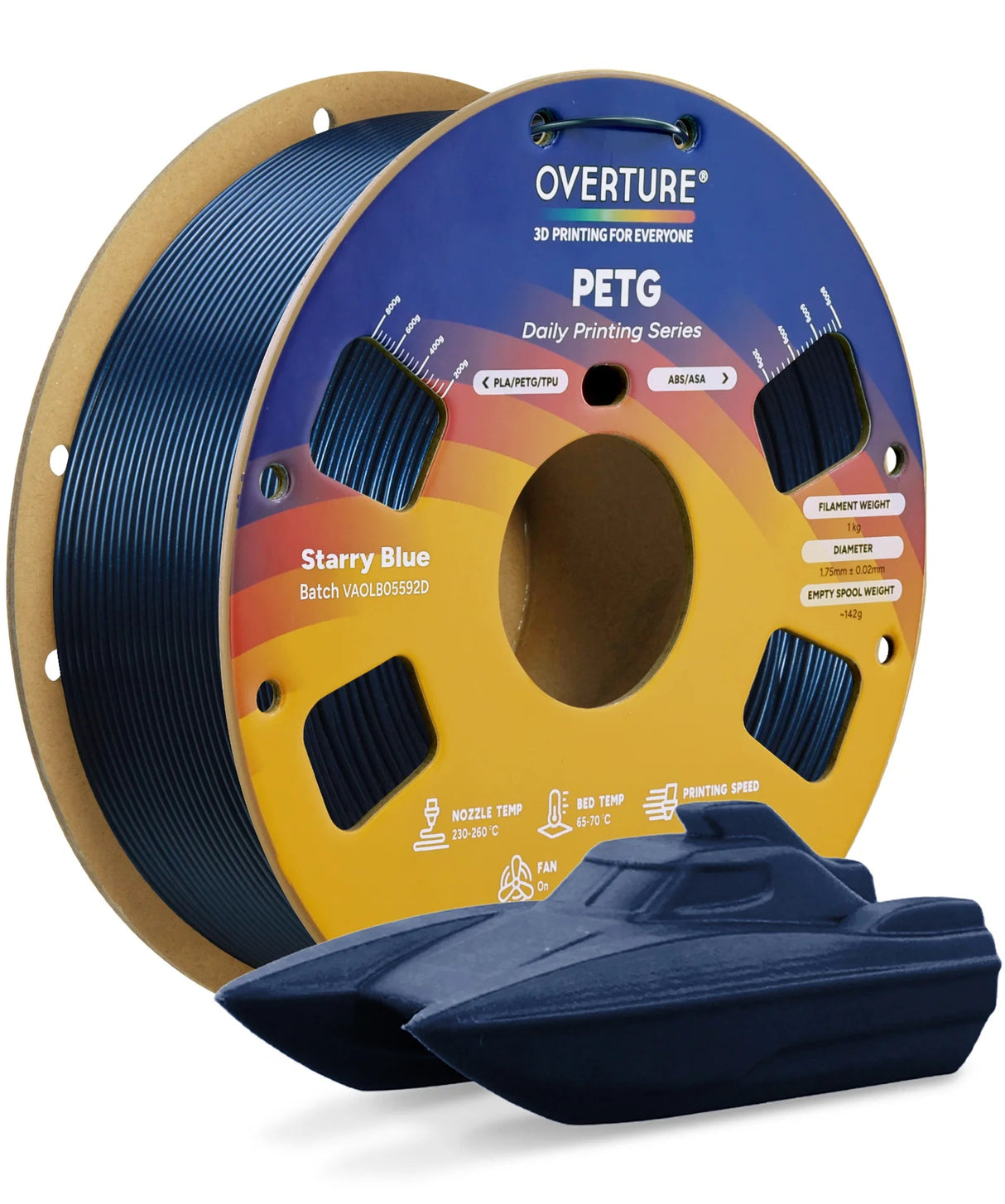

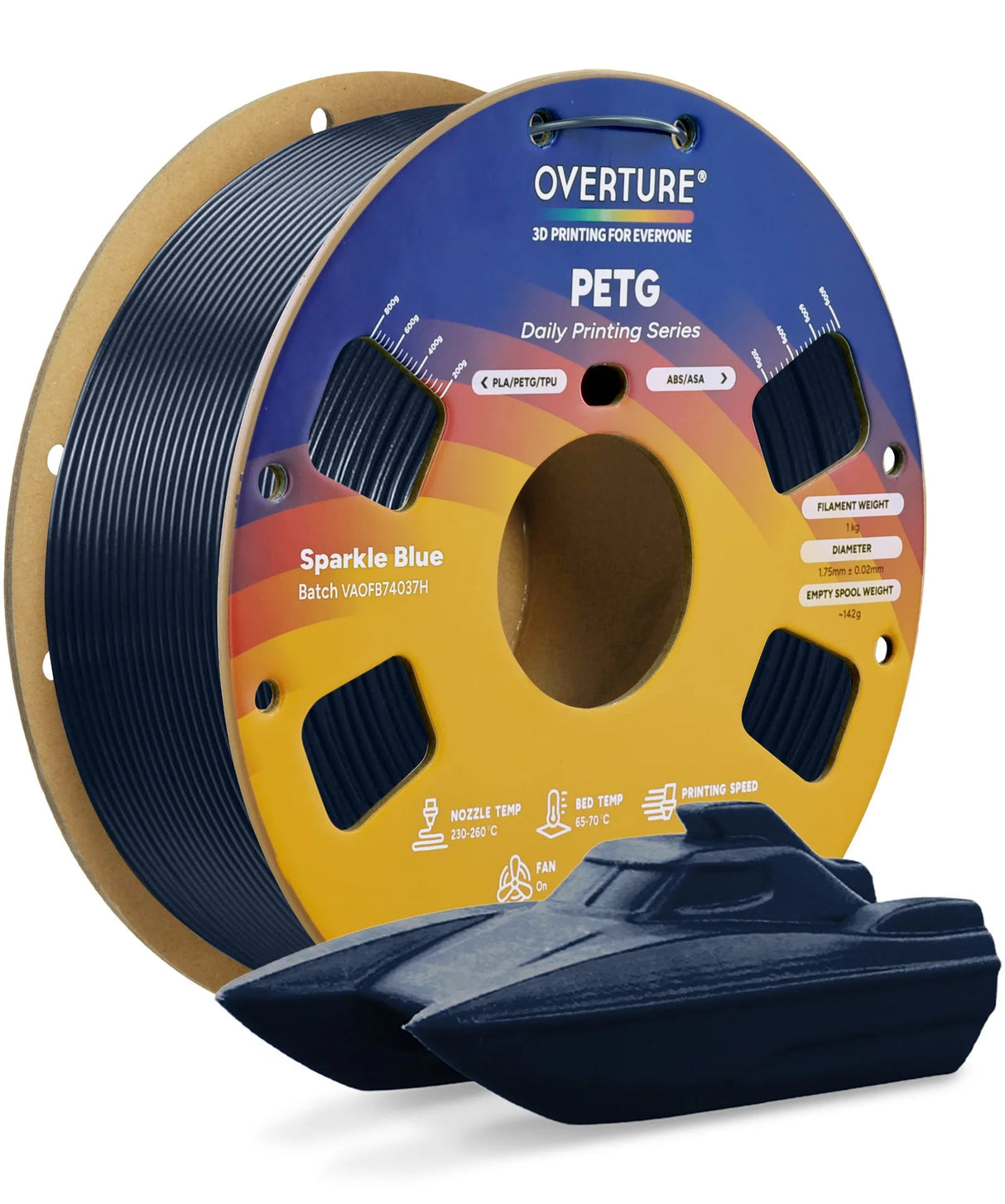

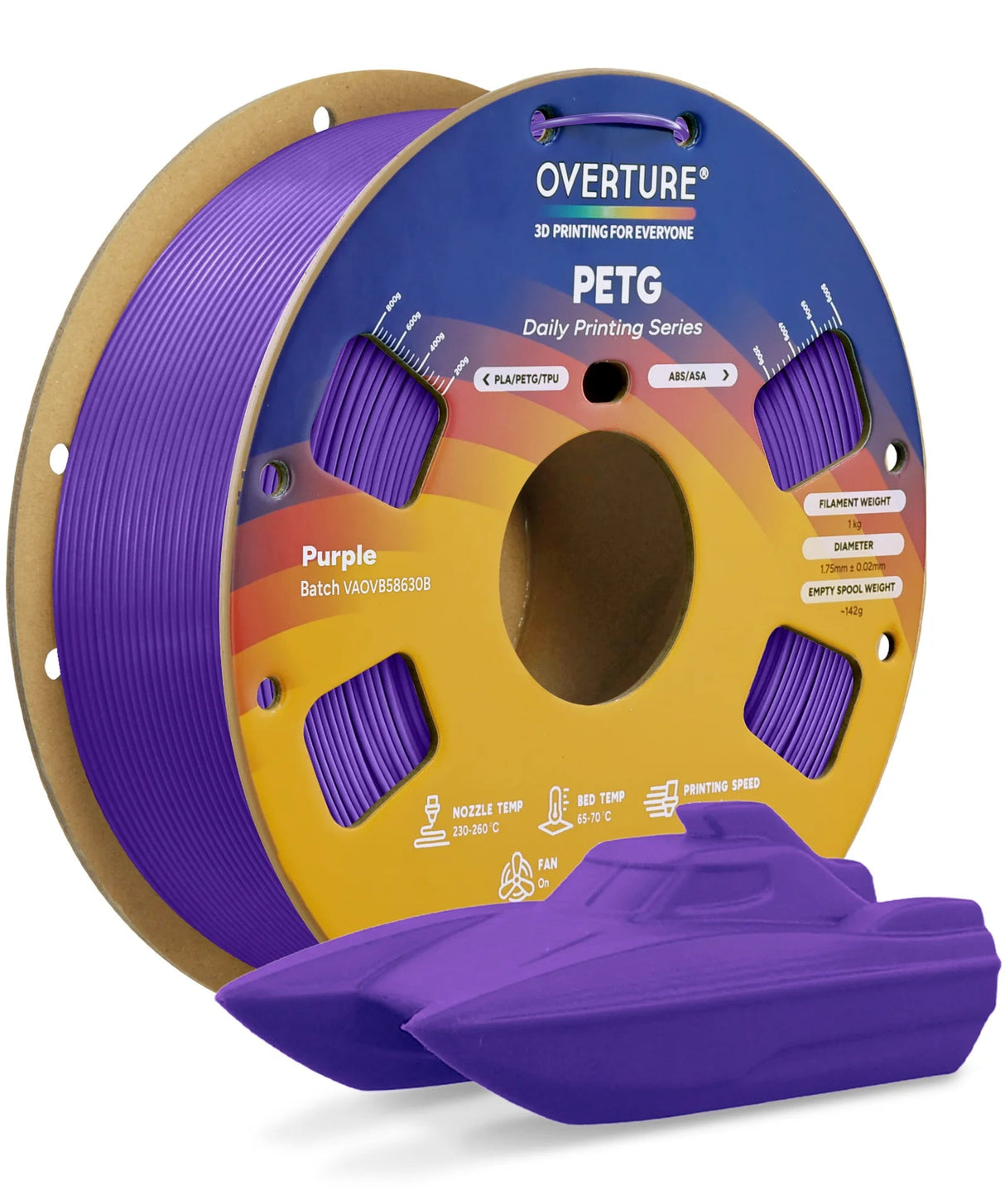

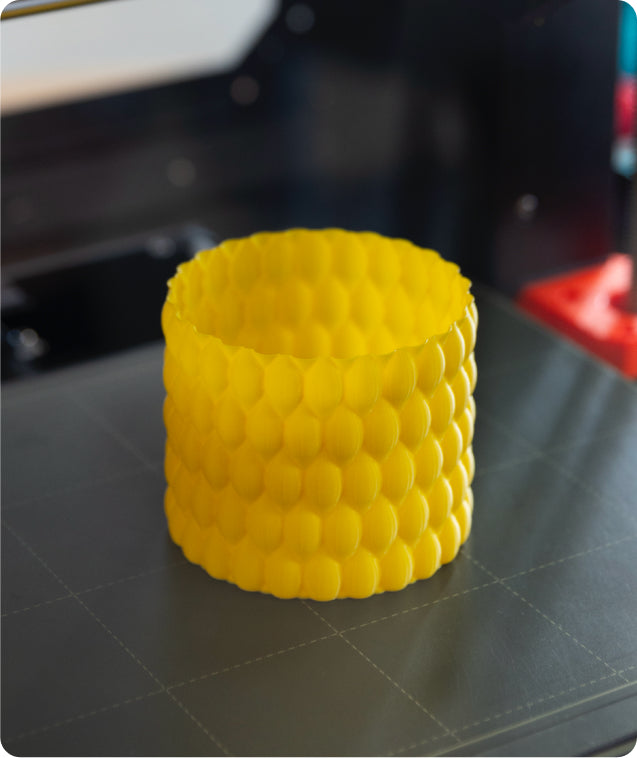

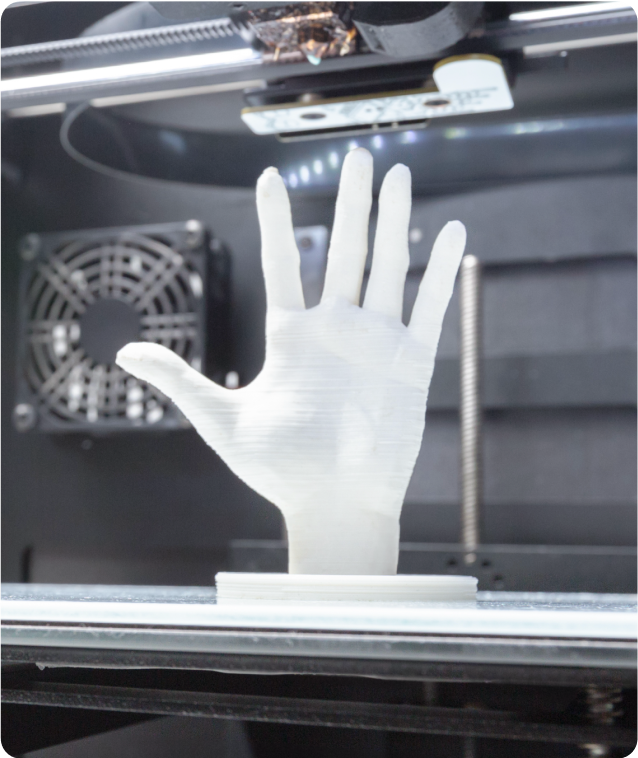

Prints Display

Recommended Printing Settings

| Nozzle temperature | 230 - 260 °C |

| Build Surface material | Textured PEI |

| Build surface treatment | None |

| Build plate temperature | 65 - 70 °C |

| Cooling fan | Turned on |

| Printing speed | < 300 mm/s |

| Retraction distance | 0.8 - 3 mm |

| Retraction speed | 20 - 80 mm/s |

| Threshold overhang angle | 60 ° |

FAQ

Why choosing Overture PETG instead of PLA?

Why choosing Overture PETG instead of PLA?

PETG has notable advantages in heat resistance and chemical resistance. It also provides higher impact strength and is generally priced lower than Overture PLA, offering a cost-effective option for durable prints.

Do I need to dry Rock PETG before printing as same as PETG? Drying setting recommended?

Do I need to dry Rock PETG before printing as same as PETG? Drying setting recommended?

PETG-based filaments are sensitive to moisture, so we recommend drying them at 65°C (149°F) for 7 hours. Avoid prolonged drying times, as excessive heat can cause the filament to become brittle and unsuitable for printing. For storage, keep it in a sealed container with desiccants to maintain low humidity levels.

Is PETG moisture sensitive? What are the drying recommendations?

Is PETG moisture sensitive? What are the drying recommendations?

Yes, PETG is sensitive to moisture, so we recommend drying under 65°C (149°F) for 7 hours. Avoid extended drying times, as this can lead to the filament becoming brittle and unsuitable for printing. For storage, keep it in a sealed container with desiccants to maintain low humidity levels.

What should I do if Rock PETG is warping or not adhering well to the bed?

What should I do if Rock PETG is warping or not adhering well to the bed?

If you experience warping or poor bed adhesion with PETG, try increasing the bed temperature to around 70-80°C (158-176°F) and use a suitable bed surface like glass or PEI, possibly applying a light adhesive like glue stick or hairspray. Ensure the initial layer height is calibrated correctly and print at a slower speed for the first layers. It may also help to reduce or turn off the cooling fan during the first few layers and check that the nozzle height is not too high. These adjustments should improve bed adhesion and reduce warping.

How does the cooling fan impact PETG print quality and layer adhesion?

How does the cooling fan impact PETG print quality and layer adhesion?

Use the cooling fan to improve surface quality by reducing stringing, but be aware that it may weaken layer adhesion. Conversely, not using a fan can enhance layer adhesion and strength. Whatever you choose, the initial layer should have minimal cooling (around 0% or very low) to ensure good bed adhesion.

What should I do if PETG is warping or not adhering well to the bed?

What should I do if PETG is warping or not adhering well to the bed?

If you experience warping or poor bed adhesion with PETG, try increasing the bed temperature to around 70-80°C (158-176°F) and use a suitable bed surface like glass or PEI, possibly applying a light adhesive like glue stick or hairspray. Ensure the initial layer height is calibrated correctly and print at a slower speed for the first layers. It may also help to reduce or turn off the cooling fan during the first few layers and check that the nozzle height is not too high. These adjustments should improve bed adhesion and reduce warping.

How does Overture PETG perform in terms of heat resistance?

How does Overture PETG perform in terms of heat resistance?

Overture PETG exhibits good heat resistance, with a Vicat Softening Temperature of 85.1°C, according to ISO 306 and GB/T 1633 standards. While suitable for many applications, it's important to consider that it may not perform as well as higher-temperature resistant materials.

For reference, the Vicat Softening Temperatures of other engineering filaments are as follows:

- ABS: 103.4°C

- ASA 106.2°C

- PC Professional: 110.3°C

- Easy Nylon: 181.2°C

My filament is brittle and keeps snapping. What could be the issue?

My filament is brittle and keeps snapping. What could be the issue?

Brittle filament is a sign of moisture absorption. We recommend drying the filament and storing it in an airtight bag or container.Please refer to the“Drying Time”table for suggested drying times.