Choose Filament to Compare

|

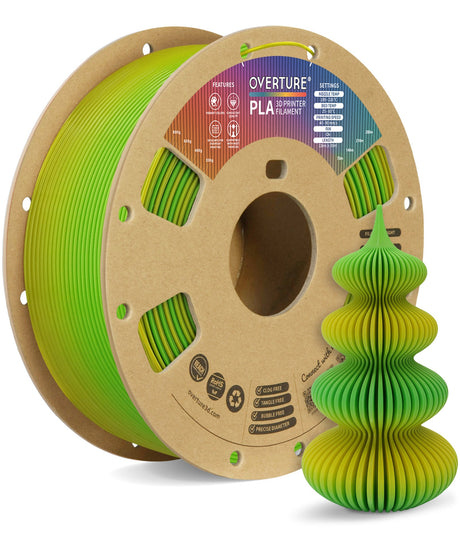

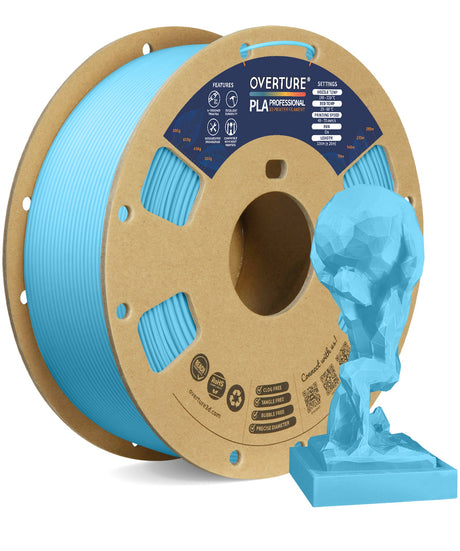

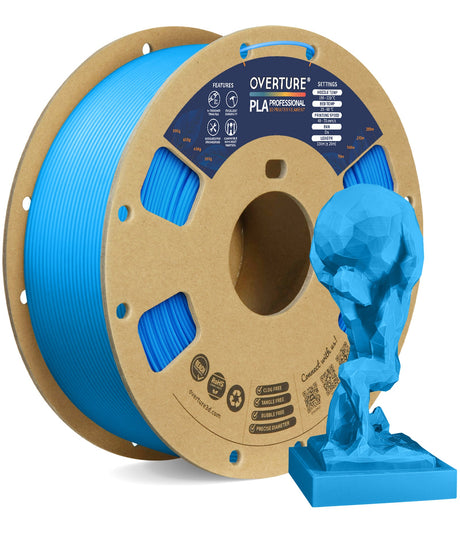

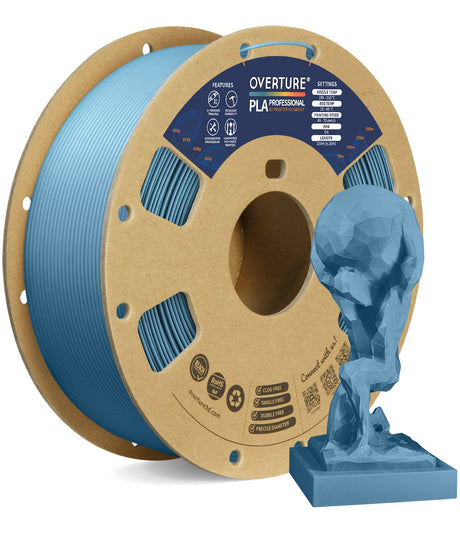

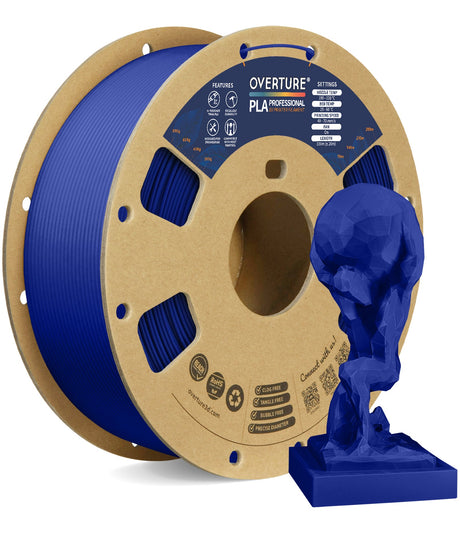

PLA SHOP NOW |

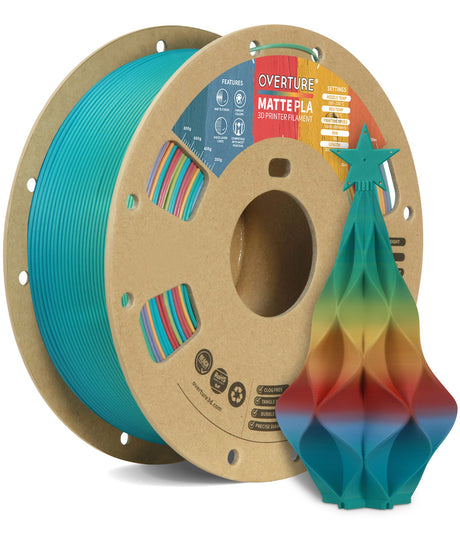

Matte PLA SHOP NOW |

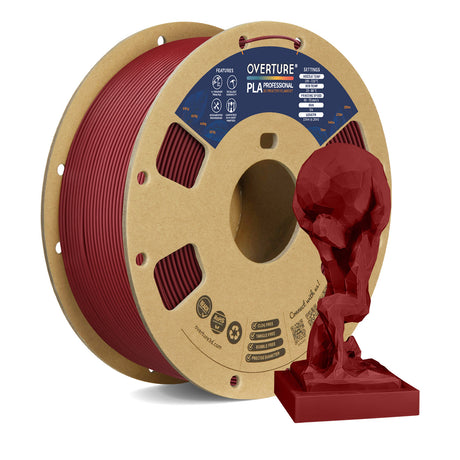

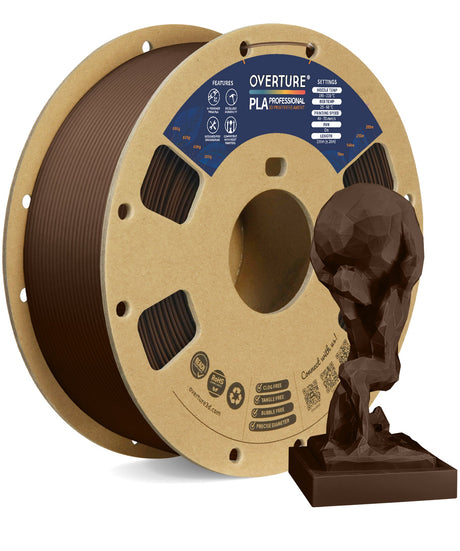

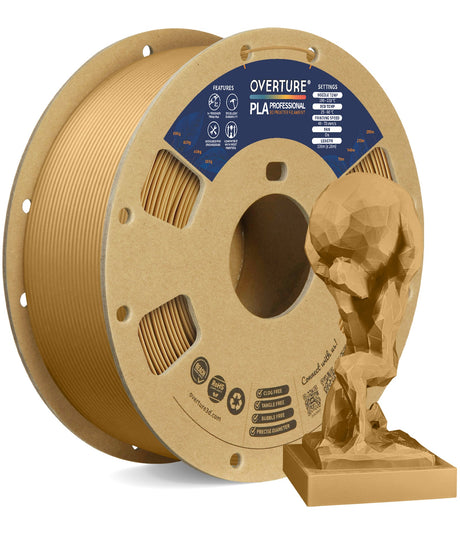

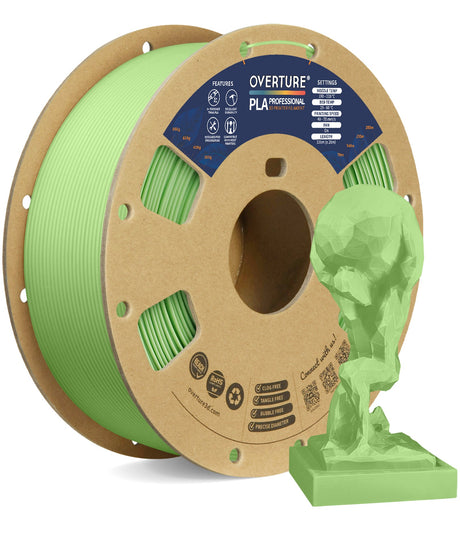

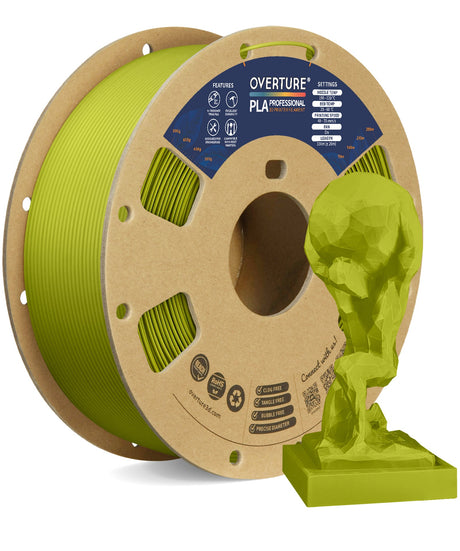

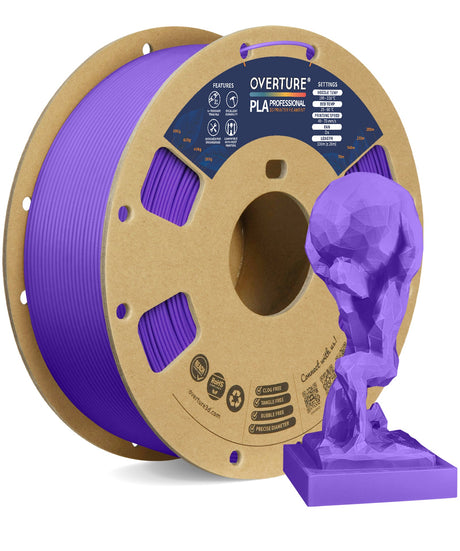

PLA Pro SHOP NOW |

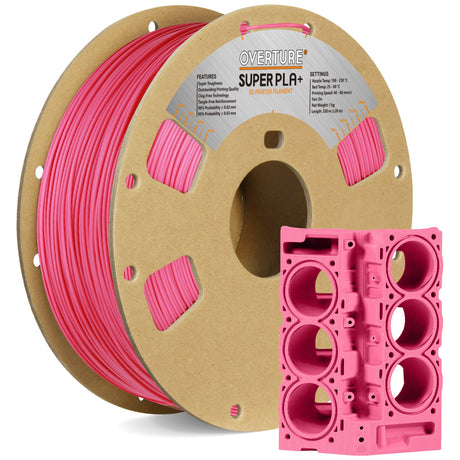

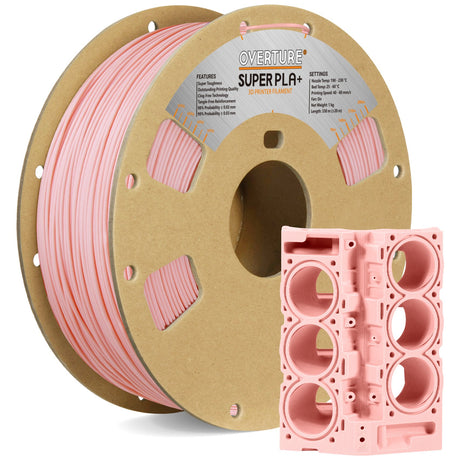

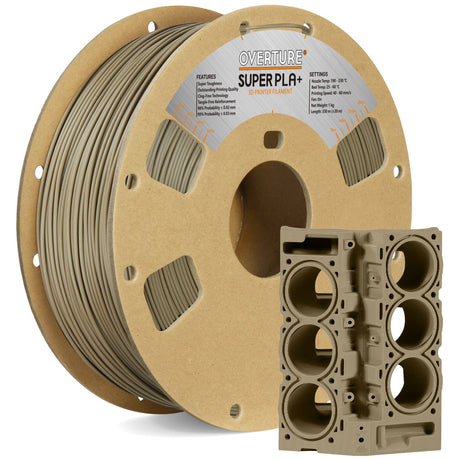

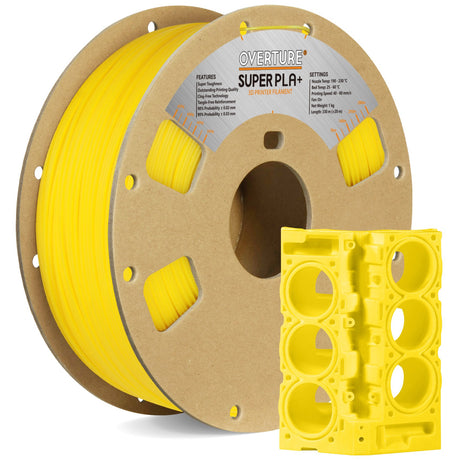

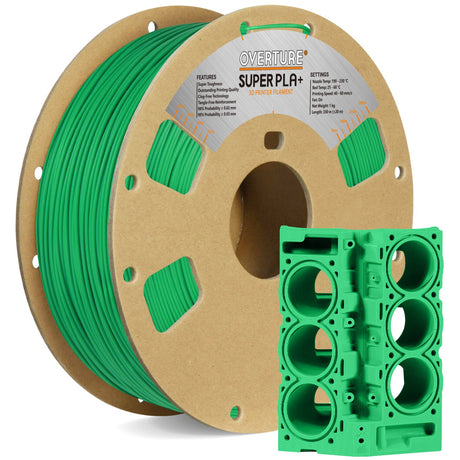

Super PLA SHOP NOW |

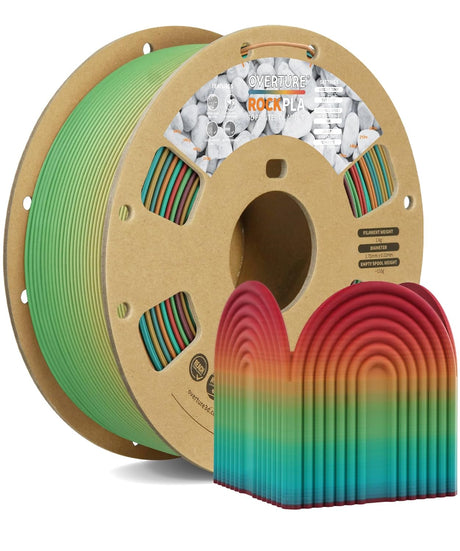

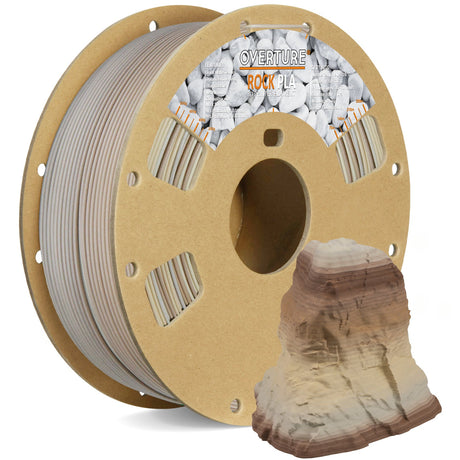

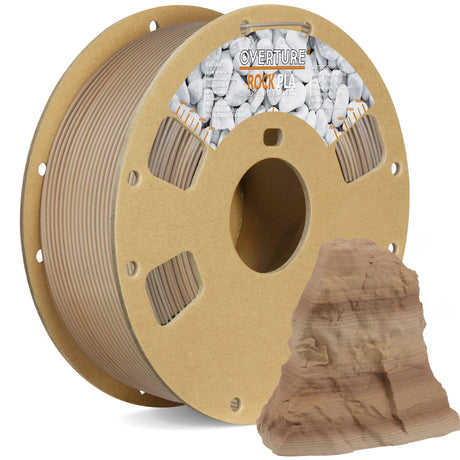

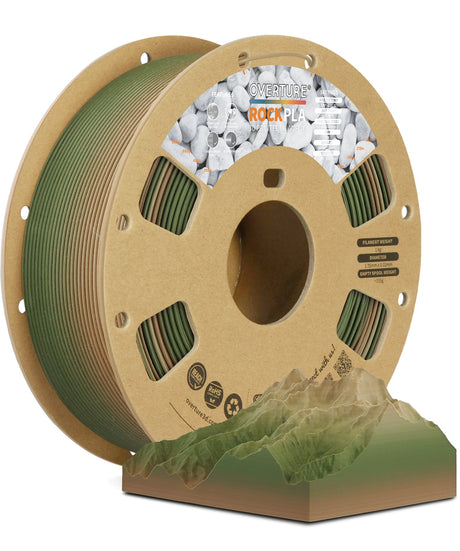

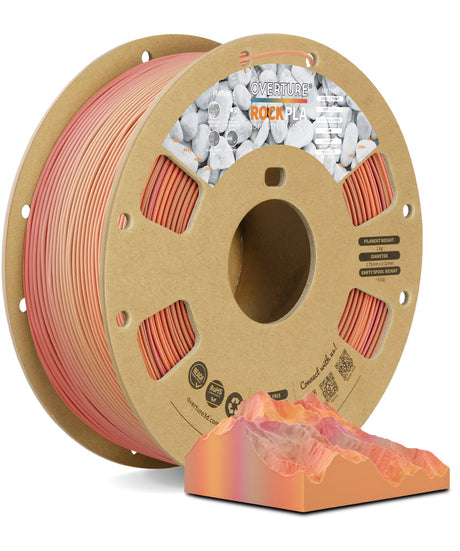

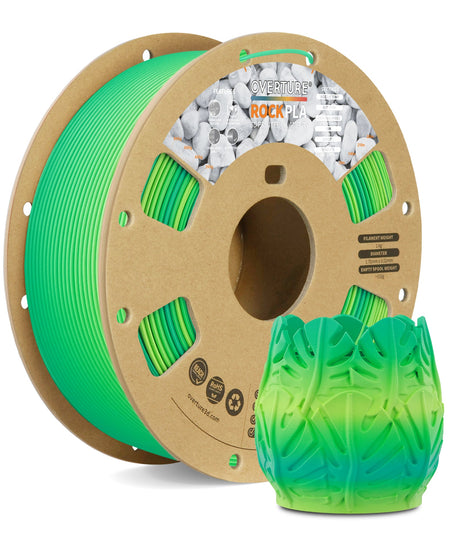

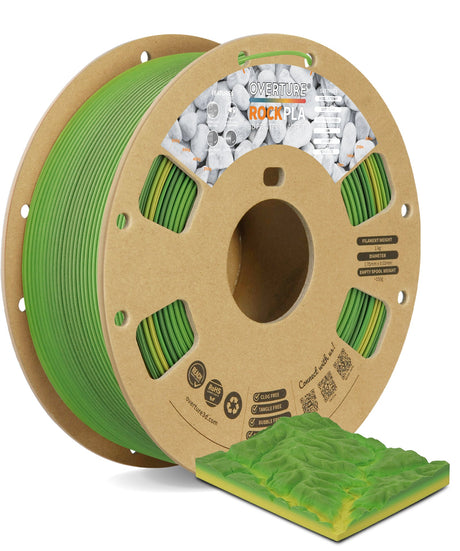

Rock PLA SHOP NOW |

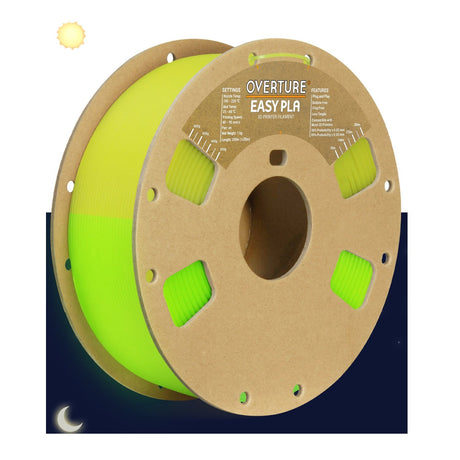

Glow PLA SHOP NOW |

Shimmer PLA SHOP NOW |

Air PLA SHOP NOW |

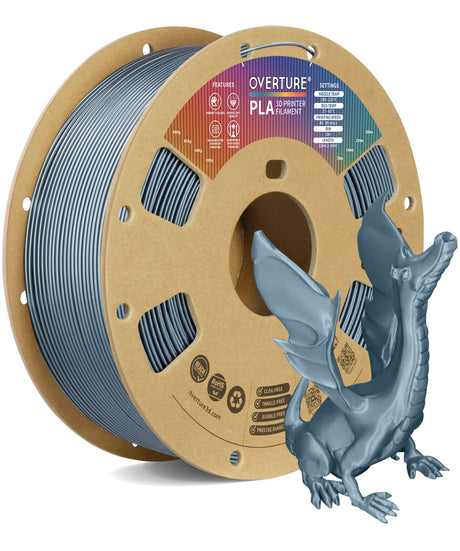

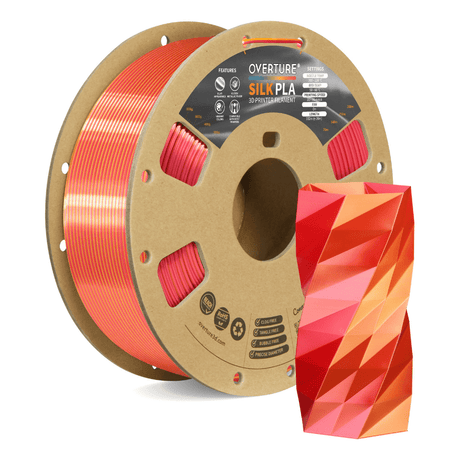

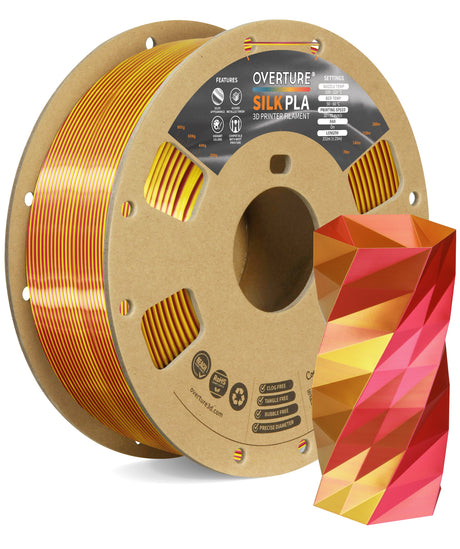

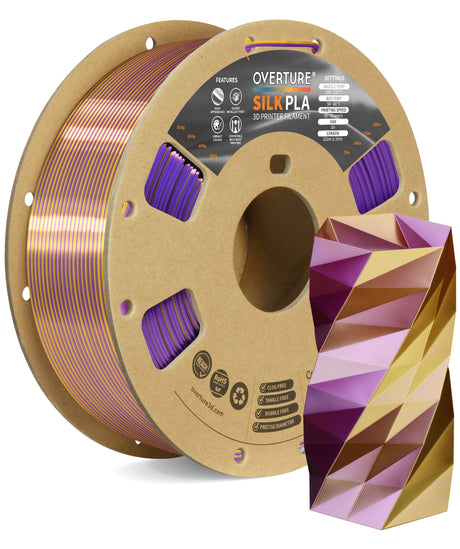

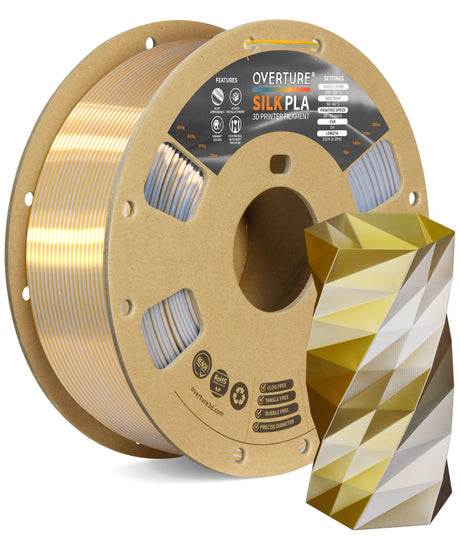

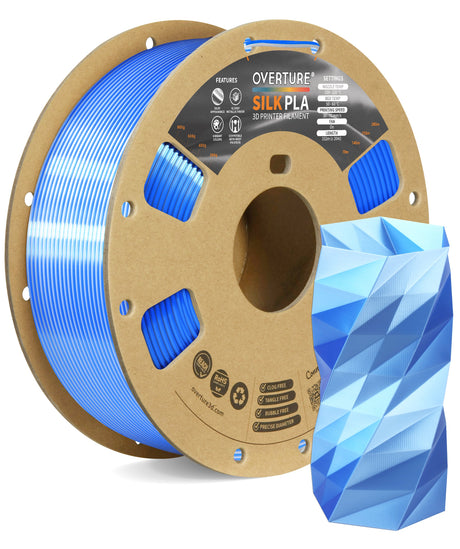

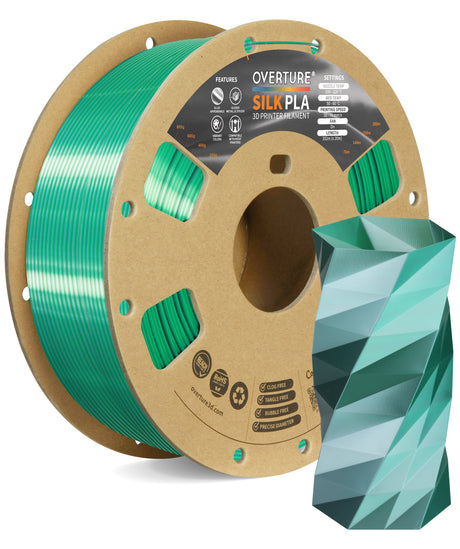

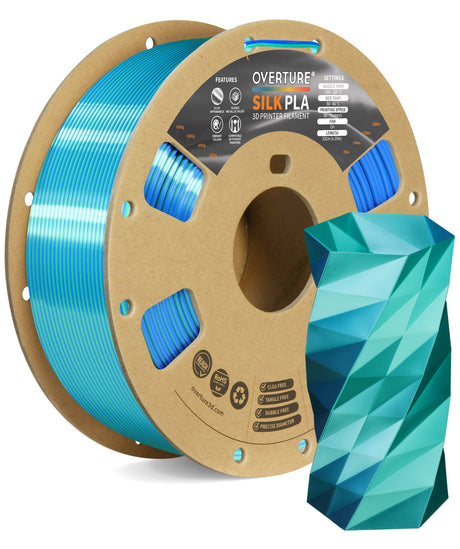

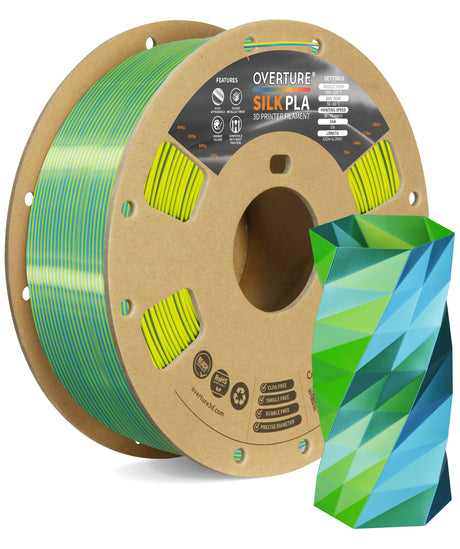

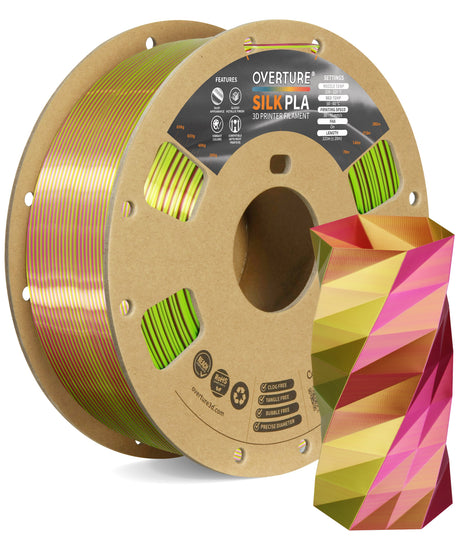

Silk PLA SHOP NOW |

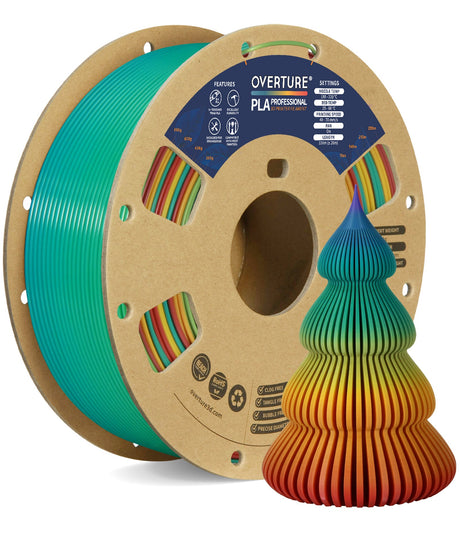

Silk PLA Dual Color SHOP NOW |

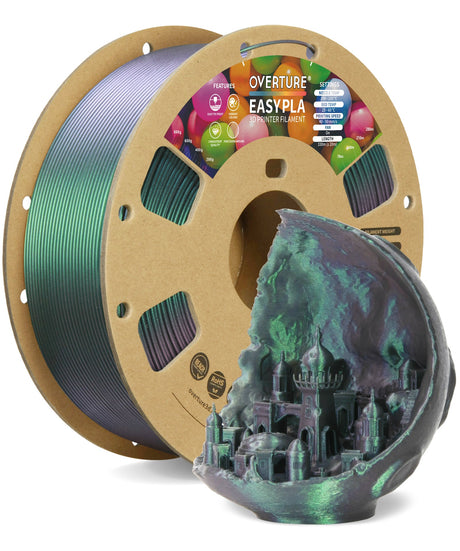

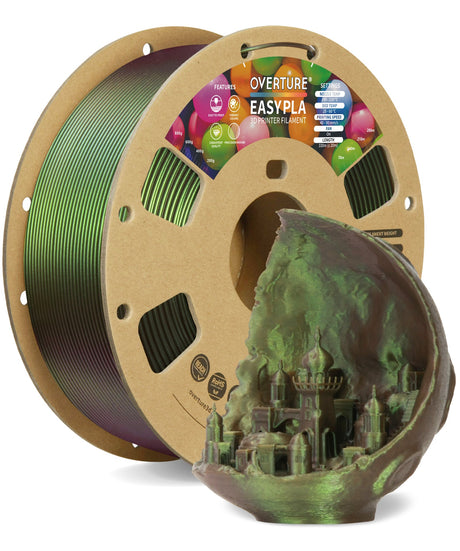

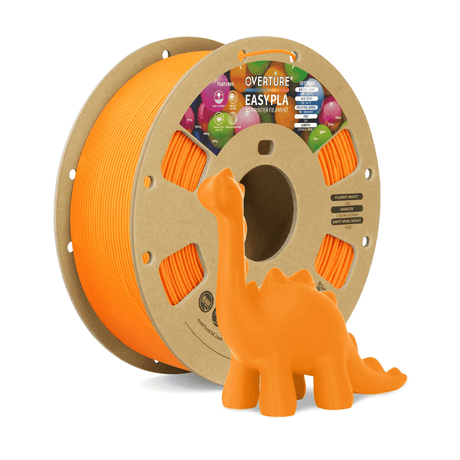

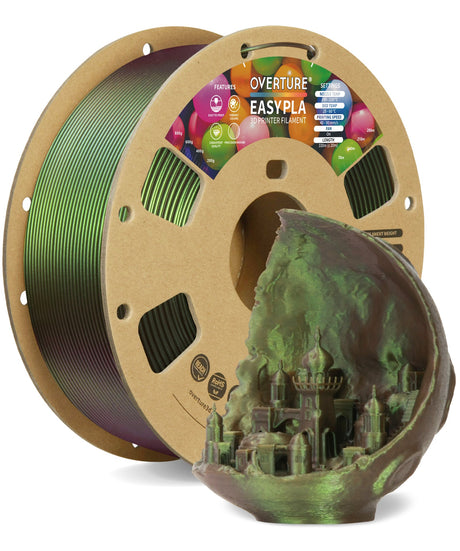

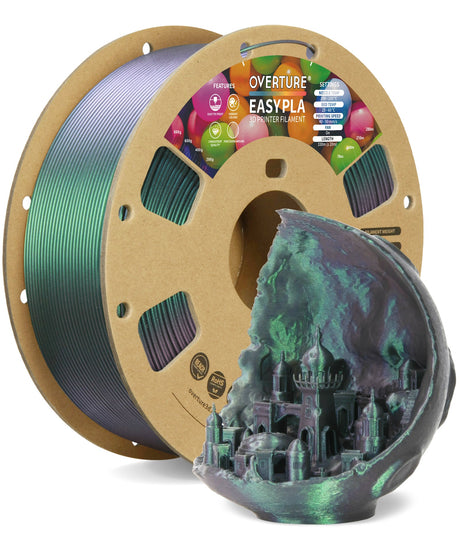

Easy PLA SHOP NOW |

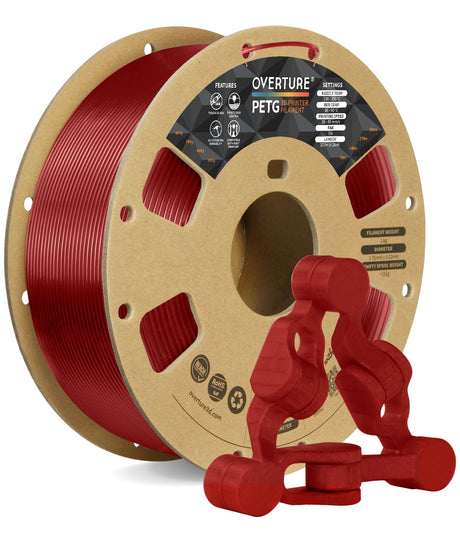

PETG SHOP NOW |

PETG Transparent SHOP NOW |

Rock PETG SHOP NOW |

TPU SHOP NOW |

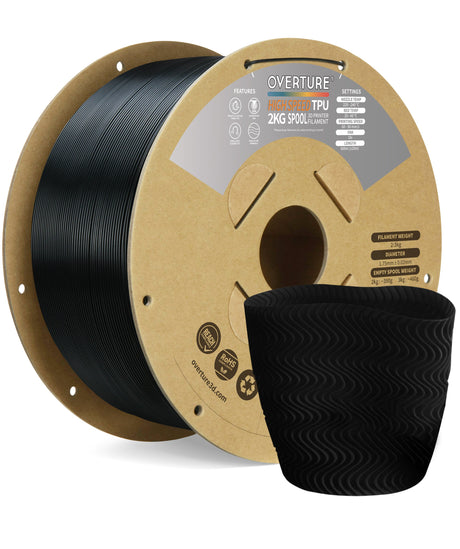

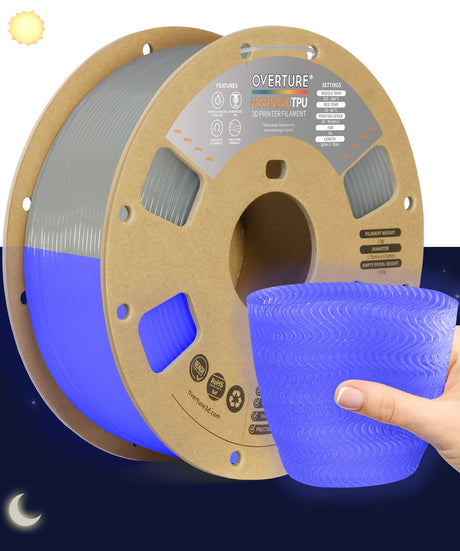

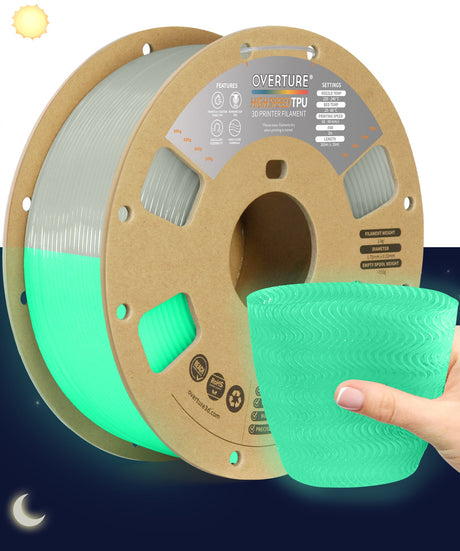

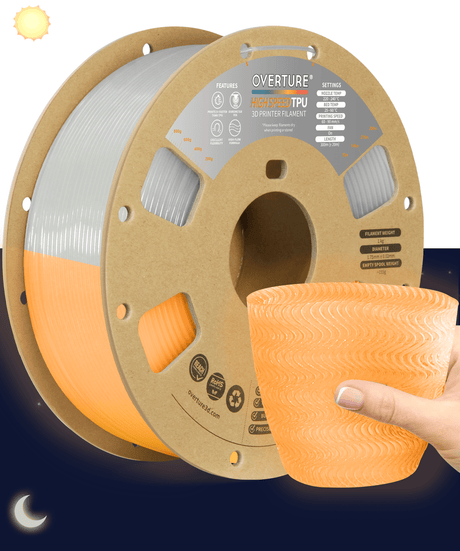

High Speed TPU SHOP NOW |

PC Pro SHOP NOW |

PC Professional Transparent SHOP NOW |

ASA SHOP NOW |

ABS SHOP NOW |

Easy Nylon SHOP NOW |

Carbon Fiber SHOP NOW | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Feature |

Great Printability and Compatiblity

Wide Color Array

Consistent quality

|

Non-glossy Finish

Reduced Layer Visibility

|

Balance of Strength and Rigidity

4X Tougher than Standard PLA

|

12X Tougher than Standard PLA

2X Tougher than ABS

|

Stone-like Finish

|

Glows in dark

|

Cost-effective

Fun Color

|

20% Lighter

Non-glossy Finish

|

Silk / Metallic Finish

|

Silk / Metallic Finish

|

Cost-effective

Fun Color

|

Balance of Toughness and Printability

Better Heat Resistance

|

Balance of Toughness and Printability

Transparent Color

|

Balance of Toughness and Printability

Transparent Color

|

Soft and Flexible

|

Print 5x Faster

Soft and Flexible

|

Excellent mechanical properties

|

Excellent mechanical properties

Transparent Color

|

High UV Resistance

Weather & Heat Resistance

|

HEAT Resistance

Minimal Odor

|

Excellenct Chemical Resistance

Abrasion Resistance

|

Non-glossy Finish

High Stiffness & Strength

|

| Technical Properties | ||||||||||||||||||||||

|

Strength

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| N/A | N/A |

|

|

|

|

|

|

|

Stiffness

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| N/A | N/A |

|

|

|

|

|

|

|

Toughness

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| N/A | N/A |

|

|

|

|

|

|

|

Layer Adhesion

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| N/A | N/A |

|

|

|

|

|

|

|

Heat Resistance

|

|

|

|

|

|

|

|

| N/A | N/A |

|

|

|

| N/A | N/A |

|

|

|

|

|

|

| Density | 1.21 g/cm³ at 21.5 °C | 1.30 g/cm³ at 21.5 °C | 1.27 g/cm³ at 22.1 °C | 1.21 g/cm³ at 21.5°C | 1.30 g/cm³ at 21.5 °C | 1.20 g/cm³ at 21.5 °C | 1.20 g/cm³ at 21.5 °C | 0.82 g/cm³ at 23 °C | 1.19 g/cm³ at 21.5 °C | 1.19 g/cm³ at 21.5 °C | 1.20 g/cm³ at 21.5 °C | 1.25 g/cm³ at 20.7 °C | 1.25 g/cm³ at 20.7 °C | 1.25 g/cm³ at 20.7 °C | 1.18 g/cm³ at 21.5 °C | 1.19 g/cm³ at 21.5 °C | 1.21 g/cm³ at 21.5 °C | 1.21 g/cm³ at 21.5 °C | 1.14 g/cm3 at 21.3 ̊C | 1.15g/cm³ at 21.4℃ | 1.12 g/cm³ at 23°C | 1.31 g/cm³ at 21.5 °C |

| Recommended Printing Settings | ||||||||||||||||||||||

| Nozzle Temperature | 190 - 220 °C | 190 - 230 °C | 190 - 220 (˚C) | 190 - 230 °C | 190 - 230 °C | 190 - 230 °C | 190 - 220 °C | 190 - 210 °C | 200 - 220 °C | 200 - 220 °C | 190 - 220 °C | 230 - 250 °C | 230 - 250 °C | 230 - 250 °C | 210 - 230 °C | 200 - 240 °C | 250 - 270 °C | 250 - 270 °C | 240 - 270 °C | 245 - 265 °C | 245 - 260 °C | 190 - 230 °C |

| Build Surface Marterial | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI, Blue Tape | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI, Blue Tape | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI, Blue Tape | OVERTURE Build Surface, Textured PEI, Blue Tape | OVERTURE Build Surface, Textured PEI | OVERTURE Build Surface, Textured PEI | PA film, PI film, Textured PEI | OVERTURE Build Surface, Textured PEI | PA film, PI film, Textured PEI | OVERTURE Build Surface, Textured PEI, Blue Tape |

| Build Surface Treatment | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None, Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | None / Applying PVA glue to the build surface | Applying PVA glue to the build surface | None | Applying PVA glue to the build surface | None / Applying PVA glue to the build surface |

| Build Plate Temperature | 25 - 60 °C | 50 - 70°C | 25 - 60 °C | 25 - 60 °C | 50 - 70°C | 25 - 60 °C | 25 - 60 °C | 25 - 60 °C | 50 - 60 °C | 50 - 60 °C | 25 - 60 °C | 80 - 90 °C | 80 - 90 °C | 80 - 90 °C | 25 - 60 °C | 25 - 60 °C | 90 - 105 °C | 90 - 105 °C | 70 - 95 °C | 80 - 100 °C | 50 °C | 50 - 70°C |

| Cooling Fan | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned on | Turned off | Turned off | Turned off | Turned off | Turned off | Turned on |

| Printing Speed | 40 - 70 mm/s | 60 - 300 mm/s | 40-70 (mm/s) | 40-60 mm/s | 60 - 300 mm/s | 40-60 mm/s | 40-60 mm/s | 30-50 mm/s | 30 - 70 mm/s | 30 - 70 mm/s | 40-60 mm/s | 30 - 50 mm/s | 30 - 50 mm/s | 30 - 50 mm/s | 20 - 40 mm/s | 60 - 90 mm/s | 30 - 50 mm/s | 30 - 50 mm/s | 30-50 mm/s | 30-70 mm/s | 30-70 mm/s | 60 - 300 mm/s |

| Raft Separation Distance | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1-0.2 mm | 0.1 - 0.2 mm | 0.1-0.2 mm | 0.1-0.2 mm | 0.1-0.2 mm | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1-0.2 mm | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1-0.2 mm | 0.1 - 0.2 mm | 0.1 - 0.2 mm | 0.1-0.2 mm | 0.1-0.2 mm | 0.1-0.2 mm | 0.1 - 0.2 mm |

| Retraction distance | 1 - 3 mm | 1 - 3 mm | 1 - 3 mm | 1-3 mm | 1 - 3 mm | 1-3 mm | 1-3 mm | 1-3 mm | 1 - 3 mm | 1 - 3 mm | 1-3 mm | 1 - 3 mm | 1 - 3 mm | 1 - 3 mm | 1 - 3 mm | 1-3 mm | 1 - 3 mm | 1 - 3 mm | 1-3 mm | 1-3 mm | 3-6 mm | 1 - 3 mm |

| Retraction Speed | 20 - 40 mm/s | 30 - 60 mm/s | 20 - 40 mm/s | 20-40 mm/s | 30 - 60 mm/s | 20 - 40 mm/s | 20 - 40 mm/s | 20-40 mm/s | 20 - 40 mm/s | 20 - 40 mm/s | 20 - 40 mm/s | 20 - 80 mm/s | 20 - 80 mm/s | 20 - 80 mm/s | 20 - 40 mm/s | 20-40 mm/s | 20 - 40 mm/s | 20 - 40 mm/s | 20 - 40 mm/s | 20-40 mm/s | 40 - 60 mm/s | 30 - 60 mm/s |

| Threshold Overhang Angle | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 60 ° | 35 ° | 35 ° | 45 ° | 45 ° | 50 ° | 50 ° | 55 ° | 60 ° |

| Pre-Printing | ||||||||||||||||||||||

| Need Drying | Not Required | Not Required | Not Required | Not Required | Not Required | Not Required | Not Required | Not Required | Not Required | Not Required | Not Required | Recommended | Recommended | Recommended | Recommended | Recommended | Not Required | Not Required | Recommended | Recommended | Recommended | Not Required |

| Drying Condition | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 50°C (122°F) for 7 hours | 65°C (149°F) for 7 hours | 65°C (149°F) for 7 hours | 65°C (149°F) for 7 hours | 70°C (158°F) for 7 hours | 70°C (158°F) for 7 hours | 75°C (167°F) for 7 hours | 75°C (167°F) for 7 hours | 75°C (167°F) for 7 hours | 75℃(167°F)for 7 hours | 95°C (203°F) for 7 hours | 50°C (122°F) for 7 hours |

Please noted that all data are tested under certain condition, and test result may vary.

For complete specifications, please visit the Data Download Page or search in our Help Center.